Article Contents

Industry Insight: 2835 Led Lights

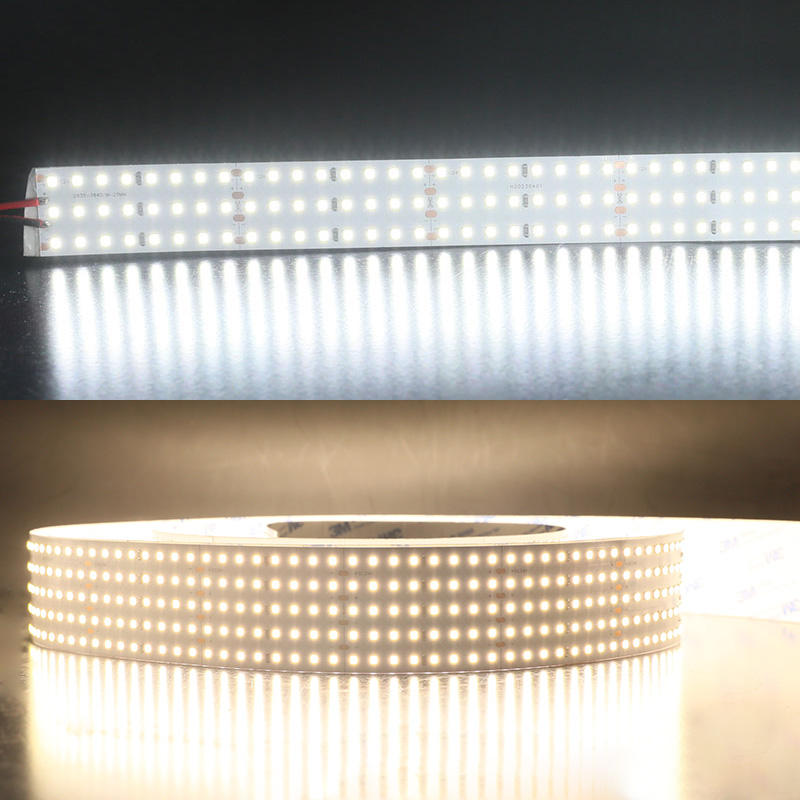

2835 Mid-Power LEDs: The Quiet Workhorse Behind Today’s Commercial & Industrial Luminaires

Why 2835 Has Become the Default Mid-Power Package

Since its introduction, the 2.8 mm × 3.5 mm mid-power package—universally known as “2835”—has displaced 3528, 3014 and 5050 in almost every volume-built luminaire. The reasons are strictly industrial:

| Driver Metric | 2835 Advantage | Impact on Fixture BOM |

|---|---|---|

| Forward Voltage | 2.8–3.2 V, single-cell compatible | Eliminates 6–9 V strings, cheaper drivers |

| Thermal pad | Bottom-slug, 2.3 W/mK MCPCB direct | 25 % lower Rth compared with 3528 |

| Luminous density | 45–55 lm @ 150 mA (0.5 W) | 120–160 lm/W system efficacy at Tj = 85 °C |

| Color binning | 1/5th or 3-SDCM structure | Uniformity in linear runs & troffer arrays |

These characteristics make 2835 the LED of choice for troffers, strip fixtures, wall packs, high-bay retrofit kits and, of course, flexible strip lights—exactly the segments where Beauty STC Lighting has shipped >180 million pieces since 1998.

Certification Reality: Why ETL & CE Are Not “Paperwork”

When a distributor in California, Ontario or Bavaria stocks 2835-based fixtures, the first question from the inspector is not “How bright?” but “Show me the file number.”

| Certificate | Standard(s) | What It Proves for 2835 Luminaires | Enforcement Risk if Missing |

|---|---|---|---|

| ETL Listed (US) | UL 1598 / UL 8750 | Dielectric, temperature, single-fault | Red-tag job site, 100 % re-inspection cost |

| ETL Listed (Canada) | CSA C22.2 #250.0 | Idem, –40 °C cold-start | Same as above |

| TUV CE (EU) | EN 60598-1, EN 62031, EN 55015 | LVD + EMC + RoHS | Customs seizure, €10 k–€50 k penalty |

Beauty STC Lighting maintains ETL file #5023748 and TUV CE reports #TUV-50-2022-0120. Every 2835 reel, panel or floodlight we ship carries the file number laser-marked on the driver housing—no separate “request for certificate” needed.

Beauty STC Lighting: 1998–Today—A Factory, Not a Trader

Located at 41th Caihong Road, Jianghai High-tech Zone, Jiangmen, Guangdong, our 28,000 m² campus houses:

8 high-speed YAMAHA SMT lines (2835 placement rate 110 kcph)

3 automatic solder-paste SPI + AOI loops (defect rate <50 ppm)

Integrating-sphere & goniophotometer lab (2 m & 0.5 m, LMS-9000B)

-40 °C ↔ +85 °C thermal cycle chamber (256-channel Tj mapping)

Since 1998 we have produced exclusively OEM/ODM lighting for exporters who require Western-grade paperwork. Our 2835 portfolio today includes:

| Product Family | Typical 2835 Count | System Efficacy | Certification | MOQ |

|---|---|---|---|---|

| 10 mm Flex Strip, 120 LED/m | 600 pcs/5 m | 160 lm/W @ 24 V | ETL, CE, RoHS | 1,000 m |

| 60 W Wall Pack | 112 pcs 0.5 W | 145 lm/W, 8,700 lm | ETL, DLC Premium | 200 pcs |

| 1 × 4 Panel (40 W) | 192 pcs 0.2 W | 130 lm/W, 5,200 lm | ETL, CE, TUV-CR | 500 pcs |

All designs are released with .IES, .LDT, TM-30, ISTMT and UL derivative reports—ready for your own DLC or ERP submission.

Next Step: From Spec Sheet to Container Load

Whether you need a 2835 strip tuned to 180 lm/W for Europe’s ERP 2025, or a 50 V constant-current strip for long-run hotel coves, our FAE team can lock bin, voltage and CCT within 48 h.

Email [email protected] or add +86-13902885704 on WhatsApp. Quote “2835-B2B-article” and receive a data pack with LM-80, TM-21 and UL derivative files within 1 hour.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

As a manufacturer with over 25 years of LED lighting expertise since 1998, Beauty STC Manufacturing Co., Ltd. upholds stringent technical standards for 2835 SMD LED products. Our ETL (USA/Canada) and TUV CE (Europe) certifications validate compliance with international safety and performance benchmarks. As a certified OEM/ODM partner, we integrate these standards into every production stage, ensuring reliable performance for global commercial and industrial applications. This section details the technical foundations of our 2835 LED solutions, emphasizing how our manufacturing rigor exceeds industry norms.

Luminous Efficacy

Luminous efficacy (lumens per watt) directly impacts energy efficiency and operational costs. Generic 2835 LEDs typically deliver 80–100 lm/W under standard operating conditions. Beauty STC’s engineered variants achieve 110–130 lm/W through optimized chip packaging, precision current regulation, and advanced thermal management. This higher efficacy reduces power consumption by 15–20% compared to industry averages while maintaining consistent light output, critical for large-scale commercial deployments where energy savings are a priority.

Color Rendering Index (CRI)

Accurate color representation is essential for retail, healthcare, and architectural applications. Generic 2835 LEDs often exhibit CRI values of 80–85, resulting in noticeable color distortion under artificial lighting. Beauty STC maintains a minimum CRI of 95 across all products, verified through spectrophotometric testing per ASTM E308 standards. This ensures true-to-life color rendering, meeting demanding requirements for high-end interior design, museum lighting, and critical visual tasks where color accuracy is non-negotiable.

IP Ratings & Environmental Protection

Environmental resilience directly impacts product longevity. Standard market offerings typically feature IP20 ratings for indoor use only, with inconsistent performance in humid or outdoor conditions due to unverified sealing processes. Beauty STC’s certified IP65 and IP67 ratings for outdoor-grade products undergo rigorous testing per IEC 60529 standards. All ratings are validated by third-party certifications including TUV CE, guaranteeing complete protection against dust ingress and water jets up to 6.3mm nozzles. This ensures reliable operation in harsh environments such as industrial facilities, outdoor signage, and marine applications.

PCB Quality & Thermal Management

The foundation of LED longevity lies in substrate quality and thermal design. Generic PCBs often use standard FR-4 with 1oz copper and thermal conductivity of 0.3–0.5 W/mK, leading to thermal runaway and premature failure. Beauty STC employs high-Tg FR-4 substrates (Tg ≥170°C) with 2oz copper traces and thermal conductivity ≥1.5 W/mK. Combined with optimized thermal pathways and aluminum heat sinks in high-power applications, our designs reduce junction temperatures by 30% compared to industry averages, extending operational life beyond 50,000 hours under continuous use.

Consistency Assurance Through Rigorous Quality Control

Consistency across production batches is non-negotiable for large-scale projects. Beauty STC implements a multi-stage quality control process including in-line photometric testing, color binning to ±3 SDCM (1/3 binning), and final validation against ETL/CE standards. Every batch undergoes thermal cycling (–40°C to +85°C) and 1,000-hour accelerated aging tests per IEC 62612, ensuring uniform luminous flux and color temperature within ±5% tolerance. This level of consistency eliminates project delays caused by mismatched lighting in commercial installations.

| Parameter | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Luminous Efficacy (lm/W) | 80–100 | 110–130 |

| CRI (Ra) | 80–85 | ≥95 |

| IP Rating | IP20 (indoor only); outdoor ratings often unverified | IP20/IP65/IP67 certified; validated per IEC 60529 with TUV CE documentation |

| PCB Material | Standard FR-4, 1oz copper; thermal conductivity 0.3–0.5 W/mK | High-Tg FR-4 (Tg ≥170°C), 2oz copper; thermal conductivity ≥1.5 W/mK |

| Thermal Management | Basic heatsinking; high thermal resistance | Optimized thermal pathways; 30% lower thermal resistance |

| Color Consistency | ±10 SDCM | ±3 SDCM (1/3 binning) |

Beauty STC’s commitment to technical excellence, backed by 25+ years of manufacturing expertise and global certifications, ensures our 2835 LED solutions meet the most demanding commercial requirements. For project-specific technical documentation or OEM collaboration, contact us at [email protected] or +86-13902885704.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – 2835 LED Solutions from Jiangmen

1. Factory Footprint & Capabilities

Beauty (STC) Manufacturing Co., Ltd. has operated from a 12 000 m² vertically-integrated plant in Jiangmen (Guangdong) since 1998. The site is organised into four ISO-9001 controlled zones: SMT, automated assembly, burn-in/ageing, and packaging. All 2835-based strips, panels, tubes and luminaires are engineered, built and certified under one roof for full traceability.

| Zone | Key Equipment | Output Capacity |

|---|---|---|

| SMT-1 | Yamaha YSM20R + MPM Momentum 8 | 150 000 2835 placements h⁻¹ |

| SMT-2 | Juki KE-3020 (dual lane) | 120 000 2835 placements h⁻¹ |

| Reflow | 10-zone Heller 1936MK5 (N₂ atmosphere) | ΔT ≤ 5 °C across PCB |

| AOI | Mirtec MV-6 OMNI 3D | 0.3 s per 2835 footprint |

2. 2835-Specific SMT Workflow

- Incoming reel audit – Lumileds, Samsung or customer-specified 2835 reels are 100 % sampled for luminous-flux, Vf and x/y chromaticity on an Everfine HAAS-2000 sphere.

- Solder-paste stencil – 0.12 mm laser-cut stainless steel; 100 % 3D paste inspection (KohYoung KY8030) before component placement.

- Placement – 2835 LEDs are picked with ±30 µm accuracy; coplanarity verified in-line.

- Reflow – Profile peaks at 245 °C (Pb-free SAC305) under nitrogen to keep LED lens below 220 °C; real-time thermal couple logging attached to each first-off panel.

- Post-reflow QC – AOI checks solder-joint shape, offset, polarity; 2 % of panels are micro-sectioned weekly for IMC thickness.

3. Ageing & Reliability Protocol

| Test | Conditions | Acceptance |

|---|---|---|

| On-line burn-in | 55 °C, 85 % RH, 100 % I nom, 4 h | 0 % dead LED, ΔFlux ≤ 3 % |

| Switch cycle | −10 ↔ +60 °C, 30 s dwell, 100 cycles | 0 % solder crack |

| L-T70 | 55 °C ambient, 700 mA (0.5 W 2835) | >50 000 h projected (IES TM-21) |

Every 2835 strip or module undergoes 100 % Hi-Pot (1 500 VAC) and 100 % functional test on a computerised bed-of-nails before packing.

4. OEM / ODM Customisation Matrix

| Parameter | Standard Offer | OEM Range | Tooling Time |

|---|---|---|---|

| PCB length | 0.5 m / 1 m / 5 m reel | 30 mm – 3 000 mm continuous | 3 days |

| LED density | 60, 120, 240 LEDs m⁻¹ | 30 – 280 LEDs m⁻¹ | No extra |

| CCT (ANSI) | 2700 K, 3000 K, 4000 K, 5000 K, 6500 K | 1800 K – 10 000 K, 2-step MacAdam | 5 days |

| CRI | Ra 80 | Ra 90 / 95 / 97 (LM-80 data provided) | 7 days |

| Input voltage | 12 V, 24 VDC | 5 V – 48 VDC, CV or CC | 5 days |

| Binning | 1/5th colour bin (Lumileds) | Customer-specific x/y quadrant | No extra |

| Packaging | Neutral white box | Private-label sleeve, retail box, anti-static tray | 7 days |

| Connector | 2.54 mm JST | Molex, Wago, terminal block, IP67 pigtail | 3 days |

Custom 2835 spectra (tunable white, 660 nm red add-on, or 365 nm UV) are available on 0.5 W and 1 W platforms with our in-house phosphor mixing lab.

5. Certification & Documentation Package

Safety: ETL cETL to UL 2108 & CSA C22.2#250.13; TUV CE to EN 60598-1/-2-21/-2-22, EN 62031, EN 62471.

Performance: LM-80 (2835 LED), ISTMT, TM-21, EN 62778 (blue-light).

Environment: RoHS 2.0, REACH 233, PFOS-free, conflict-minerals CMRT.

Shipment: IEC 61340-5-1 ESD packaging, drop-test carton (ISTA 3A).

6. Lead-Time & Logistics

Standard 2835 strip MOQ 1 000 m, 7-day ex-factory. OEM colour-bin or special-length orders 10–15 days. FCL/FTL weekly consolidation to Hamburg, Los Angeles and Dubai; DDP incoterms available for EU and US clients.

For technical schedules or BOM integration, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Optimal Application Scenarios for 2835 LED Technology

The 2835 SMD LED package has become a standard in commercial lighting due to its balance of efficiency, reliability, and versatility. With a compact form factor and proven performance across diverse applications, 2835 LEDs deliver consistent illumination for indoor and outdoor environments. This section details optimal use cases and installation best practices for contractors and project managers.

Hotels & Hospitality

2835 LEDs excel in hospitality settings where precise color rendering and ambient control are critical. The technology’s ability to produce warm, consistent light with high CRI ensures accurate skin tones and interior aesthetics, while flexible strip configurations enable seamless integration into cove lighting, under-cabinet fixtures, and accent features.

| Parameter | Typical Value | Notes |

|---|---|---|

| Color Temperature | 2700K–3000K | Warm white for inviting, comfortable atmospheres |

| CRI | ≥90 | Critical for accurate color representation in guest rooms and lobbies |

| Lumen Output | 3,000–4,500 lm/m | For 120 LEDs/m flexible strips |

| Power Density | 8–12 W/m | Optimized for thermal management in enclosed installations |

Installation Tips for Contractors:

Use aluminum extrusion channels with thermal pads to dissipate heat, especially in enclosed cove or ceiling recesses.

Pair with dimmable drivers (e.g., 0–10V or DALI) for adjustable ambiance control in guest rooms and restaurants.

Apply diffusers or frosted covers to eliminate hotspots and ensure uniform light distribution.

Verify local electrical codes for low-voltage (12V/24V) systems and ensure proper grounding.

Commercial Retail Spaces

Shopping malls and retail environments require high-brightness, uniform illumination to showcase merchandise effectively. 2835-based LED panels and high-density strips provide consistent color accuracy and energy efficiency, reducing operational costs while enhancing visual appeal.

| Parameter | Typical Value | Notes |

|---|---|---|

| Color Temperature | 4000K–5000K | Neutral white for vibrant product display and clean aesthetics |

| CRI | ≥85 | Ensures true color rendering for textiles, cosmetics, and electronics |

| Lumen Output | 5,000–7,000 lm/m | For high-density strips (150–200 LEDs/m) or 10,000+ lm for panels |

| Power Density | 10–15 W/m | Suitable for large-area coverage with minimal energy waste |

Installation Tips for Contractors:

Mount LED panels at 1.5–2m intervals for even illumination across sales floors, avoiding shadowed areas.

Use reflective backings in panel fixtures to maximize light output and reduce glare.

Integrate with smart dimming systems for dynamic lighting during peak hours or promotions.

Ensure IP20-rated products for indoor use; avoid exposed wiring in high-traffic zones.

Office Environments

Office spaces demand task-appropriate lighting that minimizes eye strain while supporting productivity. 2835 LEDs in panel and strip configurations deliver uniform, flicker-free illumination with balanced color temperatures ideal for prolonged visual tasks.

| Parameter | Typical Value | Notes |

|---|---|---|

| Color Temperature | 4000K | Neutral white for balanced focus and reduced fatigue |

| CRI | ≥85 | Supports accurate color judgment for documents and digital screens |

| Lumen Output | 3,000–4,000 lm/m | For under-desk or ceiling-mounted strips |

| Power Density | 8–10 W/m | Energy-efficient for 24/7 operational environments |

Installation Tips for Contractors:

Install strip lights under suspended ceilings or desk edges for direct task lighting without overhead glare.

Use 24V systems for longer runs (up to 10m) to minimize voltage drop and ensure consistent brightness.

Pair with occupancy sensors to automate lighting in meeting rooms and private offices, reducing energy consumption.

Ensure proper spacing between fixtures (e.g., 1.2m for 600x600mm panels) to avoid uneven illumination.

Architectural Facades

Outdoor architectural applications demand robust, weather-resistant solutions. 2835-based floodlights and IP65-rated strips provide high lumen output and durability for building exteriors, signage, and landscape lighting.

| Parameter | Typical Value | Notes |

|---|---|---|

| Color Temperature | 5000K–6500K | Bright white for clear visibility and structural highlighting |

| IP Rating | IP65 or higher | Essential for rain, dust, and UV exposure resistance |

| Lumen Output | 6,000+ lm (floodlight), 2,500 lm/m (strip) | Optimized for large-scale facade illumination |

| Power Density | 15–20 W (floodlight), 15 W/m (strip) | Robust thermal design for continuous outdoor operation |

Installation Tips for Contractors:

Mount floodlights at 45° angles to highlight architectural details without glare.

Secure strips with UV-stable silicone seals and stainless-steel mounting brackets to prevent corrosion.

Use constant-current drivers with surge protection (e.g., 6kV) to withstand voltage fluctuations.

Comply with local outdoor lighting regulations (e.g., dark-sky compliance) to avoid light pollution.

Technical Excellence & Compliance

Beauty STC Lighting’s 2835 LED solutions are manufactured to meet international standards for commercial applications. All products undergo rigorous testing for thermal stability, lumen maintenance, and longevity, with ETL (USA/Canada) and TUV CE (Europe) certifications ensuring compliance with safety and performance requirements. As a manufacturer with 26+ years of experience since 1998, we provide OEM/ODM services tailored to global project specifications, including custom color temperatures, CRI values, and form factors.

For technical specifications or project-specific support, contact our engineering team:

[email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Your 2835 LED Strip & Module Supply Base

| Established | 1998 – 25 consecutive years ISO-9001 production |

|---|---|

| Footprint | 41,000 m² Jijiangmen high-tech zone, 8 SMT lines, 2,000 m/day 2835 strip capacity |

| Compliance | ETL/cETL (US & Canada), TUV CE / RoHS, REACH, SAA, PSE, KC |

| Export | 50+ countries, 1,200+ container shipments since 2010 |

| Core 2835 Portfolio | Flexible strip 60–280 LED/m, 0.2 W – 1 W modules, CRI 80/90/97, 1800–6500 K, 24 V / 12 V / 48 V constant-voltage & constant-current platforms |

Why Global Contractors Specify Beauty STC 2835 LEDs

-

Western-market ready documentation

ETL file #5013347, TUV CE 1888-CE-19001; LM-80 & TM-21 data available for every 2835 bin code. -

Stable lumen maintenance

6,000 h LM-80 report: 96 % @ 85 °C; projected L90 > 54,000 h (Ts 65 °C). -

Factory-direct value engineering

2835 120 LED/m 24 V strip, 1,600 lm/m, 140 lm/W (4000 K) – landed cost benchmarked against Korean & US tier-1 suppliers. -

OEM/ODM in 3 weeks

PCB width 5 mm–20 mm, CCT tuning, 3-step MacAdam ellipse, custom reel length & logo print; MOQ 1,000 m. -

24 h technical response team

Photometric IES, Dialux & LDT files supplied within one working day; on-site lux calculation for strip spacing ≤ 10 m mounting height.

Next Step – Request Your 2835 Datasheet & Pilot Lot

Email: [email protected]

Mobile/WhatsApp: +86-13902885704

Quote turnaround: 12 h for standard part, 48 h for custom 2835 platform.

Ship your next project with a supplier whose 2835 strips are already illuminating retail chains, cold-rooms and high-bay retrofits across five continents.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).