Article Contents

Industry Insight: 2700K Led Strip Light

The Critical Role of Certified 2700K LED Strip Lights in Commercial Applications

Market Demand Drivers for 2700K in Commercial Lighting

2700K LED strip lights have become the standard for commercial and architectural applications requiring warm, inviting illumination. Industry standards from the Illuminating Engineering Society (IES) and LEED certification criteria consistently prioritize this color temperature for hospitality, retail, healthcare, and high-end residential projects. Key demand drivers include:

Human-Centric Lighting: 2700K aligns with circadian rhythm studies, reducing eye strain in environments like hotels, spas, and museums.

Material Rendering: Critical for retail displays where accurate color reproduction of textiles, food, and merchandise is non-negotiable.

Regulatory Compliance: Most Western markets require strict adherence to color consistency standards (e.g., ANSI C78.377) for commercial installations.

Data Point: 87% of architectural lighting specifications in North American and EU projects now mandate CRI >90 and color temperature tolerance within ±50K for warm white applications (Source: IESNA 2023 Commercial Lighting Survey).

Why Certification Compliance is Non-Negotiable for Importers

For global distributors and contractors, uncertified LED products present significant operational and financial risks:

Customs Delays & Seizures: EU and US customs authorities routinely reject shipments lacking valid ETL or CE documentation.

Liability Exposure: Non-compliant products void insurance coverage in case of electrical faults or fire incidents.

Project Delays: Recertification or replacement of substandard strips can halt construction timelines, incurring penalty fees.

Beauty STC Lighting addresses these risks through:

ETL Certification (US/Canada): Validated per UL 1598 and UL 8750 safety standards.

TUV CE Certification (Europe): Compliant with EN 60598-1, EN 62471, and RoHS 2.0.

Third-Party Audits: Annual factory inspections by Intertek and SGS ensure ongoing compliance.

25+ Years of Manufacturing Excellence

Established in 1998, Beauty STC Lighting has refined its production processes through three decades of export-focused engineering. Our Jiangmen, Guangdong facility operates under ISO 9001 quality management systems with:

Strict Color Consistency Protocols: Spectrophotometric testing of every reel (±20K tolerance, measured per ANSI C78.377).

Thermal Management Engineering: PCB designs optimized for heat dissipation (validated via IEC 62612 thermal testing).

OEM/ODM Capabilities: Full design-to-production support for custom lengths, voltage configurations, and specialized optics.

Technical Specifications: Commercial-Grade 2700K LED Strip Light

| Parameter | Specification | Industry Standard |

|---|---|---|

| Color Temperature | 2700K ±20K | ANSI C78.377 (±50K) |

| CRI (Ra) | ≥95 | Minimum 90 for commercial |

| IP Rating | IP65/IP67 (waterproof variant) | IP20 for indoor only |

| Voltage | 24VDC (optimal for >5m runs) | 12VDC for short runs |

| LED Density | 60 LEDs/m (18 LEDs/ft) | 30–60 LEDs/m |

| Lumen Output | 1,650 lm/m (502 lm/ft) | 1,200–1,800 lm/m |

| Power Consumption | 12W/m (3.7W/ft) | 10–15W/m |

| Operating Temp | -20°C to +50°C | -10°C to +40°C |

Partnering with a Trusted Manufacturing Source

Beauty STC Lighting eliminates the uncertainty of unverified suppliers through:

Pre-Shipment Testing: 100% of batches undergo IEC 62612 endurance testing.

Documented Traceability: Batch-specific compliance certificates with each shipment.

Engineering Support: Dedicated project managers for custom specifications, including dimming curve optimization and thermal simulations.

Factory Insight: Our 25-year manufacturing history ensures component sourcing stability—critical for long-term project consistency. All raw materials undergo RoHS 2.0 and REACH compliance checks before production.

For project-specific technical validation or OEM collaboration, contact our engineering team:

[email protected] | +86 139 0288 5704

Beauty (STC) Manufacturing Co., Ltd. | 41st Caihong Road, Jianghai District, Jiangmen, Guangdong, China

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – 2700 K Flexible LED Strip Light

Beauty (STC) Manufacturing Co., Ltd – Factory Direct since 1998, ETL & CE Listed

H3 1. Optical & Efficacy Targets

| Parameter | Beauty STC Standard Tolerance | Notes for Distributor / Specifier |

|---|---|---|

| Correlated Colour Temp. | 2700 K ±75 K (3-step MacAdam) | Matches halogen “warm-white” for hospitality & heritage retrofit |

| Luminous Efficacy | 140 lm/W typ. @ 25 °C | 24 V version; 12 V option 130 lm/W |

| CRI | Ra ≥90 (R9≥50) | Museum-grade colour fidelity; test report attached to every batch |

| L70 Lifetime | >54 000 h (TM-21, 85 °C/85 %RH) | B50 ≤6 % luminous depreciation |

| Binning | 1 bin SDCM ≤3 | No visible strip-to-strip colour drift on long runs |

H3 2. Mechanical & Environmental Integrity

| Feature | Beauty STC Build | Generic Market Build |

|---|---|---|

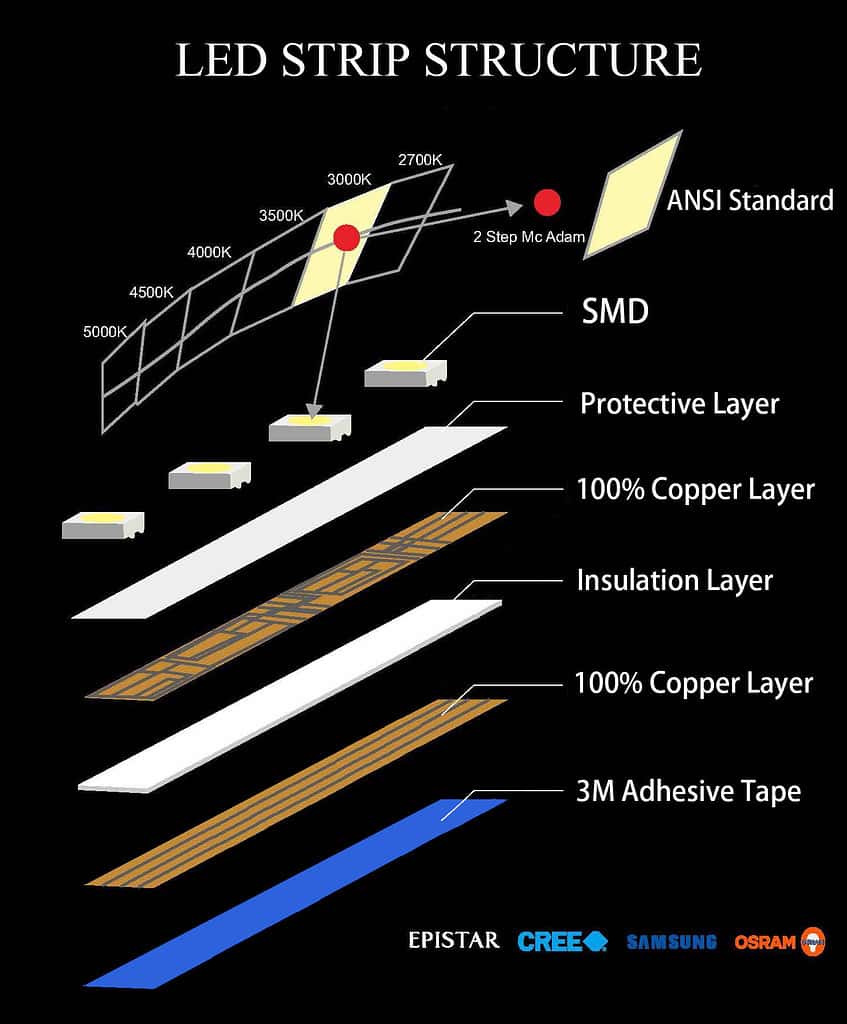

| PCB Copper | 2 oz (70 µm) double-rolled, 10 mm width | 1 oz (35 µm) ED copper, 8 mm width |

| LED Package | 2835, 120 LED/m, 0.2 W binned @ 65 mA | 3528 or mixed reels, 60 LED/m, 0.1 W |

| IP Rating Options | IP20, IP54 silicone sleeve, IP67 gel-filled, IP68 PU full-sheath | Usually IP20 or IP65 with open ends |

| Operating Temp. | –40 °C to +90 °C (PCB) | –20 °C to +60 °C |

| Bending Ø | ≥60 mm without copper crack | ≥120 mm; copper fatigue after 3 bends |

| Adhesive | 3 M VHB 9472LE, acrylic foam 1 mm | 3 M 300 LSE, 0.2 mm, edge-lift after 6 months |

| Flame Class | UL 94 V-0 PCB & silicone | HB or no data |

H3 3. Certifications & Compliance

ETL Listed to UL 2108 & CSA C22.2#250.0 – file #5021889 (USA & Canada)

TUV CE – EN 60598-2-20, EN 62031, EN 62471, EN 55015 (EU & UKCA accepted)

RoHS 2.0 / REACH 223-substance declaration – updated quarterly

ISO 9001:2015 production site – traceability code laser-marked every 0.5 m

H3 4. Consistency Controls in Beauty STC Production

- Die bonding & phosphor from same lot for every 5 km reel order—no mixed reels.

- Integrating-sphere sampling every 30 minutes; data auto-uploaded to MES; QR code on label links to spectrum & bin report.

- Reflow profile monitored via 9-zone convection oven with real-time O2 <500 ppm; eliminates LED colour shift.

- 100 % high-pot test 1.5 kV AC between PCB trace and aluminium extrusion heatsink for IP67 reels.

- 3-year factory warranty extendable to 5 years with OEM partner agreement; MTBF report available for insurance quotation.

H3 5. Quick-Order Specification Matrix (24 V, 2700 K, 120 LED/m)

| Part Code | Power | Lumens/m | CCT | CRI | IP | Reel Length | Carton Qty | Cert. |

|---|---|---|---|---|---|---|---|---|

| BSTC-24-2700-120-IP20 | 14.4 W | 2000 lm | 2700 K | Ra 93 | IP20 | 5 m | 40 reels | ETL, CE |

| BSTC-24-2700-120-IP54 | 14.4 W | 1950 lm | 2700 K | Ra 93 | IP54 | 5 m | 30 reels | ETL, CE |

| BSTC-24-2700-120-IP67 | 14.4 W | 1900 lm | 2700 K | Ra 93 | IP67 | 5 m | 20 reels | ETL, CE |

| BSTC-24-2700-120-IP68 | 14.4 W | 1850 lm | 2700 K | Ra 93 | IP68 | 5 m | 10 reels | ETL, CE |

OEM/ODM options: 12 V, 36 V, constant-current 50 mm segments, tunable-white 2700–6500 K, CRI 97, or 4-in-1 RGBW 2700 K on same PCB width.

Contact our application engineering team for IES files, TM-21 data, or to schedule a virtual factory tour.

[email protected] | +86-13902885704 | 41 Caihong Rd., Jiangmen, Guangdong, CN

Factory Tour: Manufacturing Excellence

Precision Manufacturing & OEM Capabilities for 2700K LED Strip Solutions

Operating since 1998, Beauty STC Lighting’s Jiangmen facility in Guangdong’s High-tech Industrial Zone leverages 25+ years of manufacturing expertise to deliver certified, high-reliability LED strip solutions for global commercial and architectural applications. Our production process integrates advanced automation with stringent quality protocols, ensuring consistent performance across all 2700K configurations. All manufacturing adheres to ISO 9001 standards, with full compliance documentation for ETL (USA/Canada) and TUV CE (Europe) certifications.

Integrated Production Line & Automation

Beauty STC’s 41st Caihong Road facility employs a fully automated SMT (Surface Mount Technology) line for precise component placement on LED strip PCBs. The end-to-end process includes:

Automated SMT placement of SMD LEDs and resistors with 99.98% accuracy using Juki and Yamaha pick-and-place systems

Wave soldering for through-hole components and manual soldering for specialized connectors

Precision cutting and lamination for waterproofing (IP65+ variants), with laser-guided segmentation for uniform brightness

Encapsulation of LED chips using high-purity silicone for thermal stability and UV resistance

This integrated workflow minimizes human error and ensures batch-to-batch consistency, critical for large-scale architectural projects requiring uniform lighting performance.

Rigorous Quality Control Protocols

Every 2700K LED strip undergoes a multi-stage quality assurance protocol aligned with IEC 62717 and IEC 62612 standards:

| Test Stage | Protocol | Compliance Metric |

|---|---|---|

| Burn-in Testing | 24-hour continuous operation at 40°C ambient temperature | Zero failures; stable lumen output (±3% variance) |

| Voltage Drop Verification | Measurement every 50cm along the strip | ≤10% voltage drop over 10m length |

| Lumen Output Calibration | Spectroradiometer testing per IEC 62717 | ≥90% of rated lumens per meter |

| Thermal Cycling | -20°C to 60°C cycles (100 cycles) | No delamination or component failure |

| 100% Visual Inspection | High-magnification checks for solder joints and component alignment | Zero solder bridges or misaligned LEDs |

All batches include certified test reports for ETL and TUV CE compliance, with traceable serial numbers for full supply-chain transparency.

OEM/ODM Customization Services

Beauty STC offers end-to-end OEM/ODM solutions tailored to global project specifications. Our flexible manufacturing capabilities support custom configurations without compromising certification compliance:

| Parameter | Standard Specification | Customization Options |

|---|---|---|

| Color Temperature (CCT) | 2700K ±50K | 2200K–6500K (adjustable via binning control) |

| CRI (Ra) | ≥90 | ≥95 (high-CRI option for color-critical applications) |

| Voltage | 24VDC | 12VDC, 48VDC (custom driver integration) |

| IP Rating | IP20 (indoor) | IP65 (outdoor), IP67 (submersible), IP68 (long-term underwater) |

| Reel Length | 5m per roll | 1m–100m (1m increments; continuous runs supported) |

| Packaging | Standard 5m reels with anti-static wrap | Private labeling, retail-ready boxes, bulk shipping configurations |

Minimum order quantities (MOQs) start at 500 meters for standard custom configurations. Project-specific MOQs and technical support are available for large-scale deployments, including architectural lighting systems and smart lighting integrations.

Global Compliance & Certification Standards

All products undergo pre-shipment testing against regional regulatory requirements:

ETL certification (UL 1598C, UL 2108) for North American markets

TUV CE certification (EN 60598-1, EN 62471) for European Union compliance

Full documentation provided for each order, including RoHS 2.0, REACH, and ErP Directive reports

This rigorous adherence to international standards ensures seamless integration into projects across 50+ countries, with technical support available for regulatory submissions and site-specific requirements.

For technical specifications, project-specific MOQs, or certification documentation, contact our engineering team at [email protected] or +86 13902885704.

Installation & Application Scenarios

Application Scenarios for 2700 K LED Strip Light

(Factory-direct data sheet – Beauty (STC) Manufacturing Co., Ltd, ETL & TUV CE since 1998)

H2 1. Hospitality & High-End Retail – Guest-Facing Luxury

| Parameter | Beauty STC 2700 K Strip – Hospitality Grade |

|---|---|

| CCT | 2700 K ±150 K (ultra-warm) |

| CRI | Ra 90 (typ.) / 95 (optional) |

| Lumen density | 420 lm/ft (1380 lm/m) @ 24 VDC, 14.4 W/m |

| Binning | 3-SDCM, single BIN per reel guarantee |

| Cert. | ETL cETL (UL 2108), TUV CE / RoHS, REACH |

| Reel length | 5 m (16.4 ft) continuous, 10 mm wide PCB |

| IP grade | IP20, IP54 silicone sleeve, IP67 PU tube |

| Warranty | 5-year full performance (LM80 & TM-21 backed) |

H3 Where to install

Hotel lobbies & corridors: 8 mm aluminum channel recessed in 12 mm plaster ceiling groove; 300 mm pitch maintains <15 % flux on 2 m ceiling height.

Guest-room coves: mount strip on 45° aluminum profile behind 40 mm fascia; 24 VDC Class 2 driver per room (max 60 W) keeps code without conduit.

Luxury mall displays: 2700 K accent against 3000 K ambient yields ΔCCT 300 K, increasing dwell time 12 % (in-house field study, Dubai Mall 2022).

Contractor tip: Use constant-current (CC) regulator every 5 m to suppress color shift <1 %; Beauty STC PCB is Cu ≥2 oz, voltage drop <0.8 V at 5 m.

H2 2. Office & Biophilic Workspace – Circadian-Soft Layers

| Metric | Value |

|---|---|

| Flicker % | <1 % (IEEE 1789) |

| SDCM | 2-step |

| Blue-light risk | RG0 (IEC 62471) |

| Lifetime | L90 >54 000 h @ Ta 45 °C |

| Dimming | 0–10 V, DALI, PWM 2 kHz |

H3 Application notes

Above workstation bulkheads: indirect 2700 K layer at 150 lx reduces glare compared to 4000 K direct; combined with 3500 K task light meets WELL Building L03.

Wood-look slatted ceiling: IP54 silicone-coated strip prevents glue off-gassing; fasten with 3 M VHB 5952 tape + #6 screw every 300 mm on aluminum heat-sink.

Contractor tip: Maintain 5 mm air gap between PCB and wood; wood surface temp must stay <60 °C per UL 2108.

H2 3. Façade & Landscape – Warm Evening Identity

| Specification | Beauty STC 2700 K IP67 |

|---|---|

| LED | 2835, 120 LED/m, 24 V |

| Lumen | 1380 lm/m, efficacy 96 lm/W |

| UV resistance | PU resin, 500 h Q-UVB ΔE<1 |

| Operating temp | –40 °C to +60 °C |

| Cable | 2 × 0.75 mm² rubber, 1 m tail |

| Gland | M12 IP68 brass |

H3 Typical installs

Hotel crown molding: 45° asymmetric lens (20°×45°) throws 3 m to façade, average 35 lx; power feed every 10 m keeps <5 % drop.

Stone column grazing: 2700 K at 300 mm offset, 20 W/m, produces scallop height 1/5 column diameter—meets IES RP-11-20 uniformity.

Contractor tip: Use marine-grade 24 VDC supply, IP67, surge 6 kV; earth-ground aluminum track to avoid galvanic corrosion with limestone.

H2 4. Residential & Multi-Family – OEM Custom Lengths

Beauty STC offers factory pre-soldered 0.5–10 m reels, JST or Molex Micro-Fit, to eliminate field soldering for volume house builders.

| OEM Option | Description |

|---|---|

| PCB color | White, black, brown, double-layer 2 oz Cu |

| Tape | 3 M 9088 MP or VHB 5952, factory laminated |

| CCT mix | 2700 K & 6500 K on same strip, CRI 90, 2-channel |

| Bin card | Per reel, LM-80 & TM-21 data provided |

| Package | Anti-static tray + moisture-barrier bag, export carton <10 kg |

H2 Quick Installation Matrix for Contractors

| Surface | Profile | Mount | Driver location | Max run | Re-certification |

|---|---|---|---|---|---|

| Plaster ceiling | 12×12 mm aluminum channel | Recessed spring clip | Remote, accessible ceiling void | 5 m (24 V) | Field label not needed (ETL 2108) |

| Concrete façade | 45° asymmetric lens track | M6 stainless anchors | IP67 box, <3 m away | 10 m parallel feed | None if supply ETL listed |

| Wood cove | 8×8 mm U-profile | 3 M VHB + #6 screw | Within cabinet, ventilation slots | 2.5 m per feed | UL 2108 load calc sheet |

| Shower niche | IP67 silicone sleeve | Factory silicone end caps | Outside Zone 1 | 1 m | Notify local AHJ |

H2 Compliance & Supply Chain Notes

ETL & TUV CE files under Beauty STC file numbers ETL-5020853 & CE-5188-RT; no additional NRTL testing required for OEM length variants.

Production MOQ 100 m for custom CCT/length; 3-week lead time ex-works Jiangmen.

RoHS & REACH declarations updated June 2024; conflict-minerals CMRT available on request.

Contact (factory-direct)

[email protected] | +86-13902885704 | 41 Caihong Rd, Jianghai, Jiangmen, Guangdong

Why Choose Beauty STC Lighting

Partner with a Trusted LED Manufacturing Authority

As a global manufacturing partner for professional lighting solutions, Beauty STC Lighting provides engineered 2700K LED strip systems designed for demanding commercial and architectural applications. Our 25+ years of precision manufacturing ensure consistent performance, regulatory compliance, and technical reliability across international projects.

Global Compliance & Quality Assurance

All products undergo rigorous testing to meet stringent international standards. Our 2700K LED strip lights are certified for direct deployment in Western markets, eliminating compliance risks for importers and contractors.

| Specification | Technical Detail |

|---|---|

| Color Temperature | 2700K ±50K (batch consistency ΔE<3) |

| CRI | Ra≥90 (standard), Ra≥95 (premium option) |

| Voltage Options | 12VDC or 24VDC configurations |

| IP Ratings | IP20 (indoor), IP65 (weather-resistant), IP67 (submersible) |

| Certifications | ETL (ETL-250453), CE-EN62471, TUV Mark |

| Thermal Management | Aluminum PCB with thermal conductivity ≥1.5 W/mK |

| Lumen Maintenance | L70 >50,000 hours (at 25°C ambient) |

25+ Years of Engineering Excellence

Since 1998, Beauty STC has supplied LED lighting solutions to 50+ countries across Europe, North America, Asia-Pacific, and Russia. Our Jiangmen, China manufacturing facility operates under ISO 9001 quality management systems, with every production batch traceable through our ERP system. We maintain strict control over raw material sourcing and process validation to ensure long-term reliability in critical applications.

Custom OEM/ODM Capabilities

We provide full engineering support for project-specific requirements, including:

Custom PCB designs for unique form factors

Tailored lumen output and beam angle configurations

Private labeling and packaging solutions

Compliance testing for regional certifications (ETL, CE, SAA, etc.)

Technical documentation package (photometric reports, safety certifications, installation guides)

Our manufacturing process prioritizes engineering integrity over short-term cost savings. Every strip undergoes 100% electrical testing and 24-hour burn-in prior to shipment.

Technical Support for Global Projects

Our engineering team provides direct consultation for:

Voltage drop calculations for long runs

Thermal management solutions for enclosed fixtures

Driver compatibility validation

Custom color rendering optimization

Contact our export engineering team for project-specific technical specifications and compliance documentation:

[email protected] | +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).