Article Contents

Industry Insight: 2 Pin Led Light Connector

In the rapidly evolving landscape of commercial and industrial lighting, the demand for reliable, efficient, and code-compliant electrical components has never been greater. Among these critical components, the 2-pin LED light connector stands out as a fundamental building block in modern LED lighting systems, enabling quick installation, secure connections, and long-term performance in demanding environments. Widely used in linear lighting fixtures, high-bay luminaires, panel lights, and retrofit solutions, 2-pin connectors must meet rigorous safety and durability standards—especially in large-scale applications where maintenance access is limited and system uptime is critical. Certifications such as ETL and CE have become essential markers of quality, ensuring that connectors comply with North American and international safety, electromagnetic compatibility, and environmental regulations. These certifications not only facilitate market access but also provide engineers, contractors, and facility managers with confidence in product reliability and code compliance.

At the forefront of this technology is Beauty (STC) Manufacturing Co., Ltd., a trusted name in the LED components industry since its establishment in 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-performance 2-pin LED connectors designed specifically for commercial and industrial applications. Combining robust materials, precision manufacturing, and rigorous testing protocols, Beauty STC’s connectors meet or exceed ETL and CE requirements, offering superior conductivity, thermal stability, and resistance to vibration and environmental stress. As buildings, warehouses, and industrial facilities increasingly transition to LED-based lighting for energy efficiency and longevity, Beauty STC continues to play a pivotal role in enabling safe, scalable, and future-ready lighting solutions across global markets.

Technical Specs & Certifications

The term ‘2 pin LED light connector’ refers specifically to the electrical connector component used in LED lighting systems, not the complete luminaire. It is critical to clarify that lumens per watt (lm/W), Color Rendering Index (CRI >90), and IP ratings are performance characteristics of the entire LED light fixture or module, not the connector itself. The connector is a passive interconnection device enabling power delivery to the LED light engine. Beauty STC Manufacturing Co., Ltd. designs and manufactures these connectors to stringent standards to ensure they reliably support the performance specifications of the final lighting product.

Beauty STC’s 2-pin LED connectors, such as our proprietary STC-2P series, are engineered for optimal electrical performance and durability. They utilize high-conductivity copper alloy contacts with precision gold or nickel plating to minimize contact resistance and voltage drop, typically maintaining resistance below 10 milliohms per contact pair. This low resistance is essential to prevent power loss and heat generation at the connection point, thereby supporting the overall system efficiency (lm/W) of the luminaire by ensuring minimal energy is wasted as heat within the connector. Poor quality connectors with higher resistance directly degrade the effective lumens per watt output of the complete fixture.

Regarding CRI, the connector itself does not influence color rendering. CRI is a property of the LED chip, phosphor formulation, and driver electronics within the light source. However, Beauty STC connectors contribute indirectly by providing a stable, low-resistance connection that prevents voltage fluctuations or arcing which could cause inconsistent LED performance or color shift over time. Our connectors undergo rigorous thermal cycling and high-temperature operational life testing to ensure dimensional stability and contact integrity under load, safeguarding the consistent light output and color quality demanded by high-CRI (>90) applications.

IP ratings apply to the entire luminaire assembly, indicating protection against dust and moisture ingress. Beauty STC manufactures 2-pin connectors specifically designed for integration into IP-rated fixtures. Our connectors feature precision-molded thermoplastic housings (typically UL94 V-0 rated polycarbonate or PBT) with integrated silicone or EPDM rubber gaskets. These gaskets create a secondary seal when mated within the fixture housing, contributing to the overall IP65, IP66, or IP67 rating of the assembled luminaire. Beauty STC connectors undergo independent IP certification testing as part of the fixture assembly process to verify seal performance under standardized conditions.

Beauty STC’s commitment to quality is paramount in our connector manufacturing. All connectors are produced in ISO 9001 certified facilities with 100% automated in-line testing for contact resistance, dielectric strength (typically 500 VAC min), and mechanical mating force. We adhere strictly to IPC standards for electronic interconnects and implement rigorous material traceability. Each batch undergoes accelerated life testing simulating 50,000+ mating cycles and 10,000 hours of thermal stress at 85°C/85% RH to ensure long-term reliability in demanding environments. This meticulous attention to detail ensures Beauty STC connectors provide the robust, maintenance-free performance required for commercial, industrial, and outdoor lighting applications where fixture efficiency, color fidelity, and environmental resilience are non-negotiable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key manufacturing hubs. The Jiangmen factory is designed to support high-volume production of LED lighting products with a strong emphasis on quality, efficiency, and technological integration.

The facility is equipped with advanced SMT (Surface Mount Technology) production lines, which are essential for the precise and automated assembly of LED lighting components. These SMT machines are capable of handling high-speed placement of small and complex electronic parts onto printed circuit boards (PCBs), ensuring consistent soldering quality and high throughput. The use of automated optical inspection (AOI) systems integrated into the SMT lines allows for real-time defect detection, enhancing product reliability and yield.

To ensure long-term performance and durability, Beauty STC implements rigorous aging tests at its Jiangmen factory. Completed LED light units undergo extended operational testing under controlled thermal and electrical conditions, typically running for 4 to 12 hours or more depending on product specifications. This aging process helps identify early-life failures, ensuring that only stable and reliable products reach customers. Environmental testing chambers are also used to simulate various operating conditions, further validating product robustness.

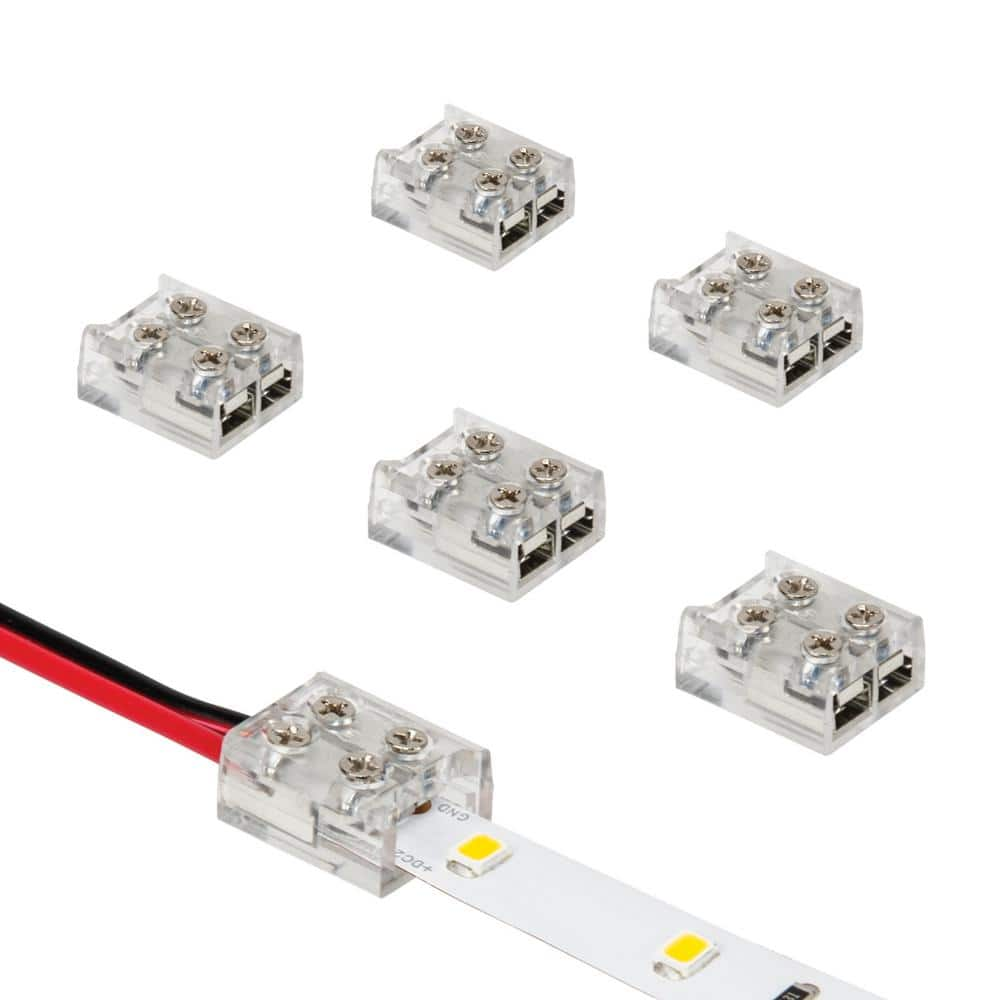

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities and welcomes custom lighting solutions, including products featuring a 2-pin LED light connector. The company can design, prototype, and mass-produce LED lighting fixtures with customized connector types, mechanical configurations, electrical parameters, and form factors to meet specific client requirements. Their engineering team works closely with clients to ensure compatibility, safety compliance, and performance optimization. The 2-pin connector configuration is commonly used in low-voltage LED applications such as strip light connectors, panel lights, and modular lighting systems, and Beauty STC has extensive experience integrating such connectors into OEM designs with reliable mating cycles and secure electrical contact.

Overall, the Jiangmen factory combines automated manufacturing, strict quality control, and flexible customization to support global clients in the residential, commercial, and industrial lighting markets.

Application Scenarios

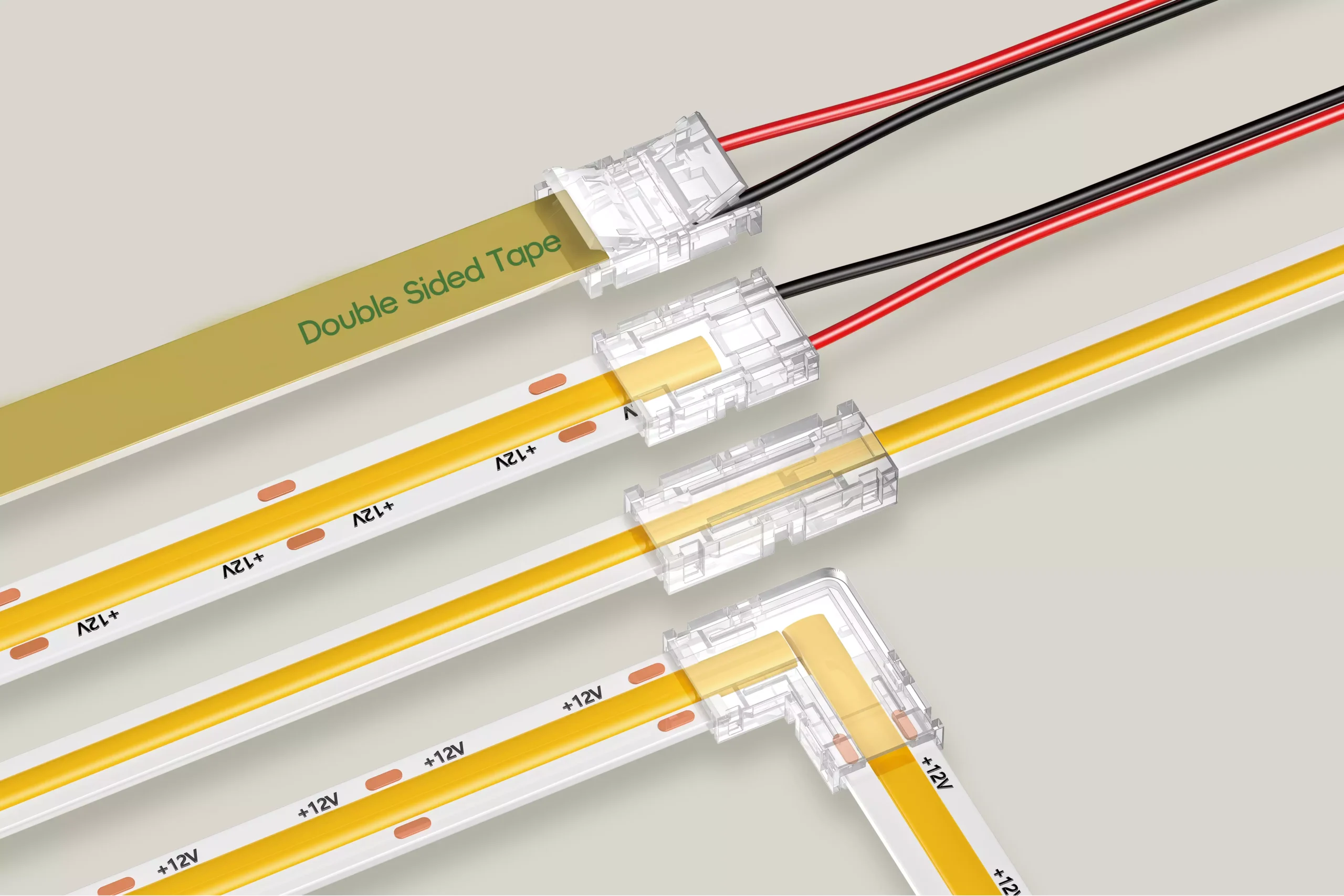

The 2-pin LED light connector, commonly used for low-voltage DC LED strip lighting systems operating at 12V or 24V, finds specific and valuable applications within hotels, malls, and offices due to its simplicity, ease of installation, and modularity. Its primary role is facilitating quick connections and disconnections for linear LED strips, enabling flexible layouts and simplified maintenance. In hotels, these connectors are frequently employed for cove lighting in lobbies, corridors, and high-end guest room headboards or under-cabinet lighting in minibars, where discreet, adjustable illumination is required. They allow electricians to easily cut strips to precise lengths for custom architectural features and enable housekeeping or maintenance staff to quickly disconnect sections for cleaning or replacement without rewiring the entire run. Within malls, 2-pin connectors prove essential for flexible track lighting systems guiding customers through walkways, for accent lighting within retail display cases requiring frequent product changes, and for under-rail or valance lighting in food courts where sections might need periodic access for cleaning or menu updates. The plug-and-play nature minimizes downtime during tenant fit-outs or seasonal display modifications. Offices utilize these connectors extensively for task lighting under desks or workstations, within partition wall systems for ambient glow, and for architectural cove lighting in reception areas or conference rooms. This supports the modern need for adaptable workspaces, allowing quick reconfiguration of lighting zones during office layout changes and simplifying the replacement of individual strip segments should a section fail, reducing disruption to employees.

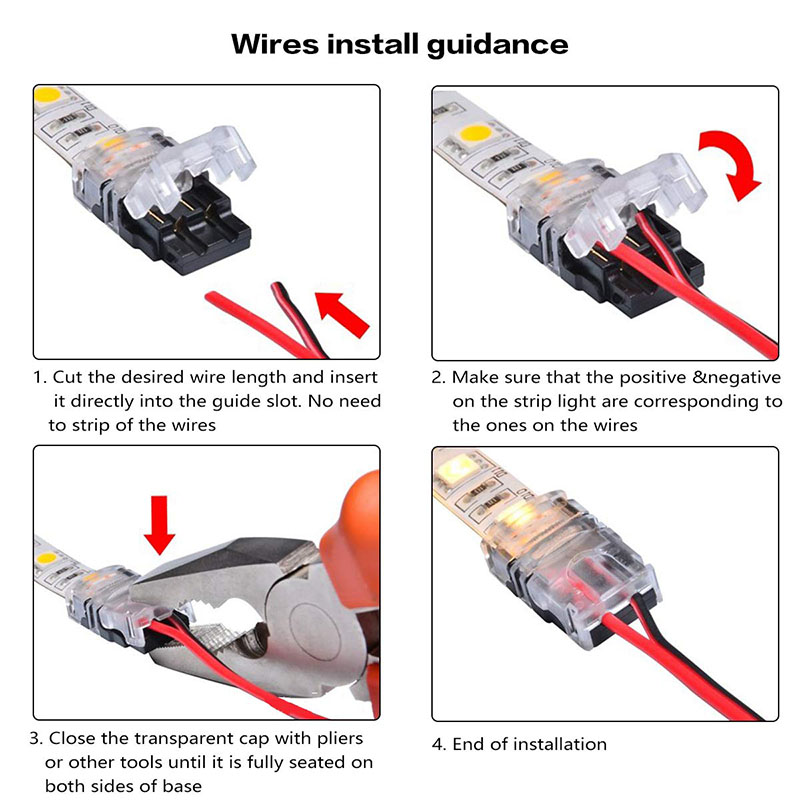

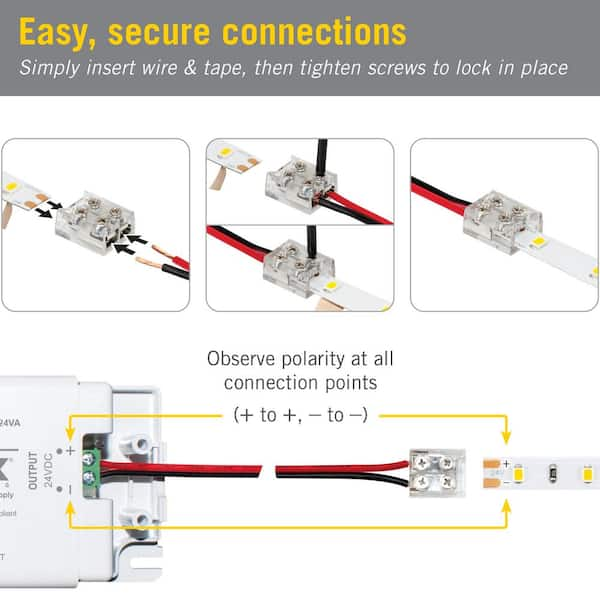

Critical installation tips must be strictly followed to ensure safety, longevity, and optimal performance in these commercial environments. Always verify the connector’s voltage and current rating matches the LED strip specifications and the power supply’s output, never exceeding the connector’s maximum amperage to prevent overheating and potential fire hazards. Ensure polarity is absolutely correct during connection; reversing positive and negative leads will damage the LED strip and is a common oversight. Before inserting the stripped wire ends into the connector terminals, meticulously twist the fine strands together to prevent stray wires from causing shorts, and confirm the insulation is fully seated against the connector body to avoid exposed conductors. For permanent commercial installations, soldering the connections followed by heat-shrink tubing application over each terminal provides significantly superior reliability and vibration resistance compared to relying solely on the connector’s spring terminals, which can loosen over time in high-traffic areas. Maintain adequate strain relief by securing the LED strip and cable a few centimeters before the connector using clips or adhesive, preventing tension on the connection point itself which is a frequent failure mode. Always install connectors within accessible locations or provide sufficient service loops, never burying them behind drywall or in inaccessible ceiling plenums without junction boxes, as mandated by electrical codes for future maintenance. Finally, in areas prone to moisture like hotel bathrooms near vanities or mall food court zones, only use connectors rated for the specific IP level required, typically with silicone seals, and ensure the connector orientation prevents water ingress along the cable. Adhering to these practices ensures the 2-pin connector delivers the intended ease of use and reliability in demanding commercial lighting applications.

Why Choose Beauty STC Lighting

Looking for a reliable and high-quality 2 pin LED light connector solution? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED lighting components. Our precision-engineered 2 pin connectors ensure secure connections, excellent conductivity, and long-lasting performance for a wide range of lighting applications.

At Beauty STC, we combine advanced manufacturing techniques with strict quality control to deliver products that meet international standards. Whether you’re a distributor, contractor, or OEM, we offer competitive pricing, custom solutions, and professional support tailored to your needs.

Take the next step in enhancing your lighting projects with dependable connectivity. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can become your preferred partner in LED lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.