Article Contents

Industry Insight: 2 Pin Connector For Led Strip

In the rapidly evolving landscape of commercial and industrial lighting, reliable and efficient components are essential to ensuring performance, safety, and compliance. Among these critical elements, the 2-pin connector for LED strips has emerged as a fundamental building block in modular lighting systems, enabling quick installation, seamless maintenance, and scalable design flexibility across a wide range of applications—from warehouse high bays and retail display lighting to industrial workspaces and architectural cove lighting. As energy efficiency and system longevity become top priorities, the demand for high-quality, code-compliant connectors that meet rigorous safety standards such as ETL and CE has never been greater. These certifications ensure that components operate safely within specified electrical parameters and are suitable for use in both North American and international markets.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED connectivity and lighting solutions for over two decades. Renowned for engineering precision and unwavering commitment to quality, Beauty STC delivers robust 2-pin connectors that support stable power transmission, resist environmental stressors, and comply with global safety certifications including ETL and CE. Trusted by lighting manufacturers and system integrators worldwide, Beauty STC continues to set industry benchmarks by combining durable design with the scalability required for today’s demanding commercial and industrial environments.

Technical Specs & Certifications

The request contains a critical technical misconception that requires immediate clarification before addressing specifications. A 2-pin connector for LED strips is a passive electrical component solely responsible for power delivery and mechanical attachment. It does not generate light and therefore possesses no inherent lumens/watt efficiency rating or Color Rendering Index (CRI) value. These metrics are properties exclusively of the LED strip itself, determined by the semiconductor chips, phosphor composition, driver electronics, and optical design. Specifying lumens/watt or CRI for a connector is physically impossible and reflects a fundamental misunderstanding of lighting component roles.

Regarding IP ratings, this is the only relevant parameter for the connector in your query. Beauty STC’s 2-pin connectors are engineered for environmental resilience. Our standard offering includes IP65-rated connectors for basic moisture and dust resistance in covered outdoor or high-humidity indoor applications, achieved through precision-molded silicone gaskets and seamless cable gland integration. For fully submerged or high-pressure washdown environments, we provide IP67 and IP68 variants with double-sealed contact chambers and marine-grade thermoplastic housings rated for 1-meter submersion up to 30 minutes (IP67) or continuous immersion under controlled conditions (IP68). All IP claims are rigorously validated per IEC 60529 standards through第三方 testing with documented reports available to clients.

Connector performance directly impacts the LED system’s operational efficiency and longevity. Beauty STC utilizes 0.5mm² oxygen-free copper (OFC) conductors with 99.99% purity and gold-plated phosphor bronze contacts to minimize voltage drop. Our connectors maintain contact resistance below 10mΩ per pin even after 500 mating cycles, preventing the power loss that would otherwise degrade the effective lumens/watt of the connected LED strip. Poor-quality connectors with higher resistance cause localized heating and voltage sag, forcing the LED driver to compensate and reducing overall system efficacy by up to 8% in extreme cases.

Beauty STC’s quality differentiation lies in our vertical manufacturing control and material science expertise. Every connector undergoes 100% automated contact resistance testing and high-potential (hi-pot) dielectric strength verification at 1500V AC. We reject industry-standard PVC for housings in favor of UL94 V-0 rated polycarbonate blends with UV stabilizers, preventing yellowing and brittleness in sunlight exposure. Our gold plating thickness exceeds 0.8μm (vs. typical 0.3μm in budget connectors), eliminating oxidation issues that cause flicker in CRI>90 LED systems where stable current is critical for color consistency. This commitment to precision ensures our connectors maintain the integrity of high-performance LED strips without introducing efficiency losses or reliability risks that would compromise the lumens/watt and CRI specifications of the lighting system.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is equipped with advanced surface mount technology (SMT) production lines, enabling high-precision assembly of LED lighting components. These SMT machines are fully automated and integrated with pick-and-place systems, reflow soldering ovens, and automated optical inspection (AOI) equipment to ensure consistent quality, high yield rates, and efficient throughput for LED strip and module manufacturing.

The facility places strong emphasis on product reliability and performance. As part of its quality control process, Beauty STC conducts comprehensive aging tests on its LED products, including LED strips and connectors. These aging tests simulate extended operational conditions under controlled temperature and electrical loads to verify long-term stability, color consistency, and electrical integrity. This rigorous testing regimen ensures that all products meet international standards and customer-specific requirements before shipment.

Regarding OEM capabilities, Beauty STC has extensive experience in providing customized manufacturing services. For components such as the 2-pin connector for LED strips, the company supports full OEM production. This includes custom molding of connector housings, selection of contact materials, wire gauge and length customization, labeling, and packaging according to client specifications. The factory can accommodate low to high-volume production runs, with engineering support available for design validation and prototyping. With its in-house tooling, molding, and assembly capabilities, Beauty STC offers a flexible and responsive OEM solution tailored to the needs of global lighting brands and distributors.

Application Scenarios

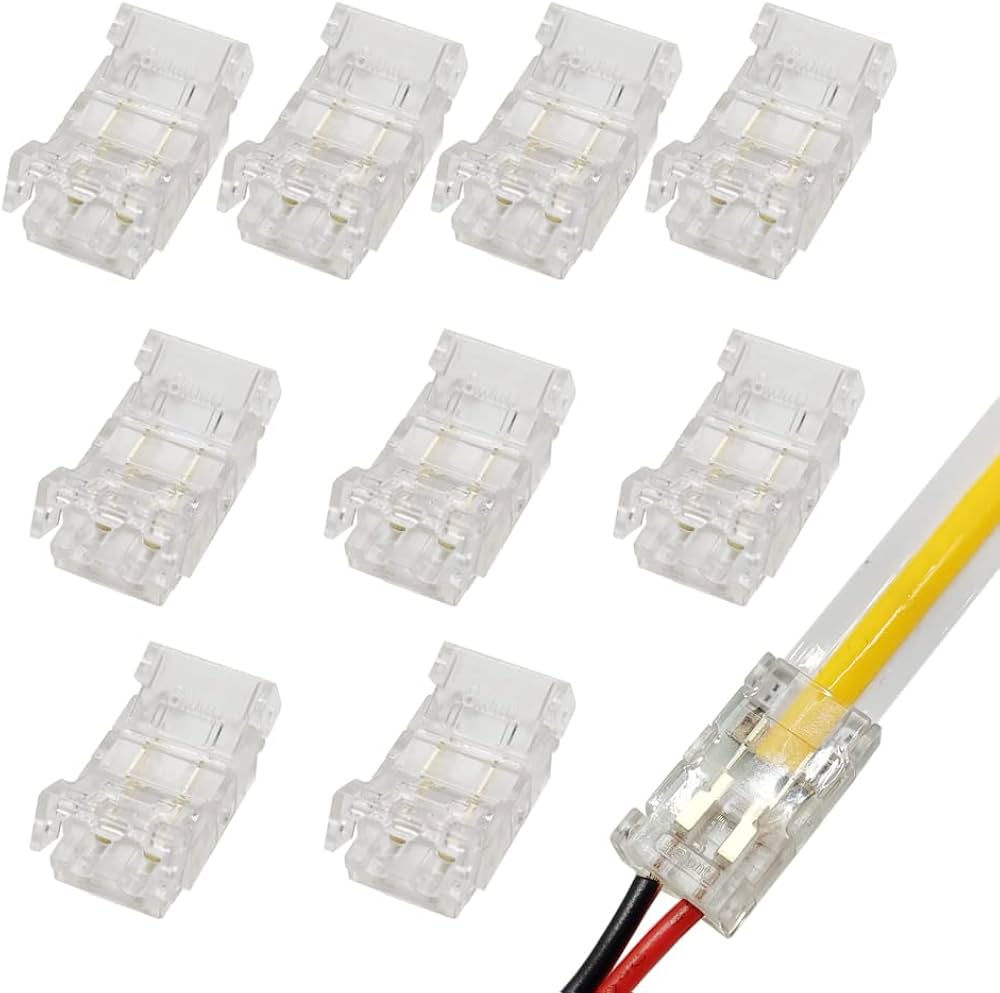

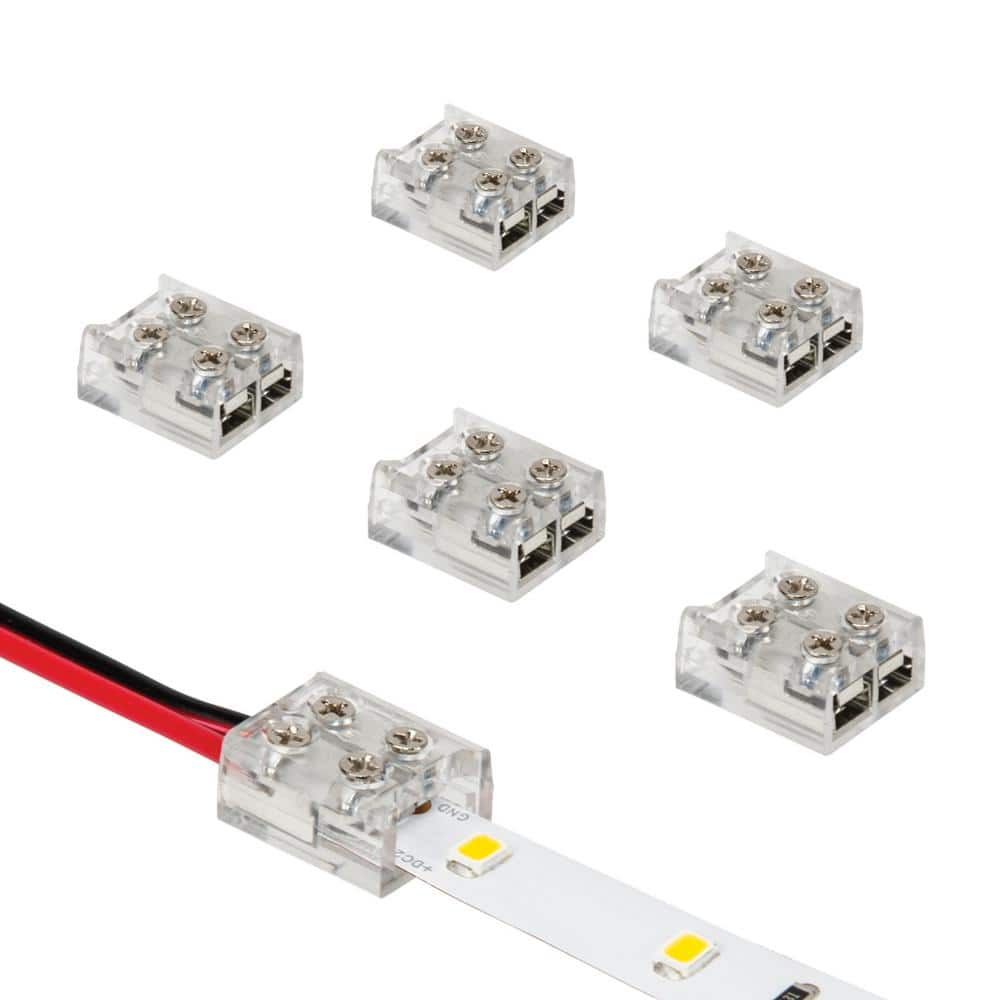

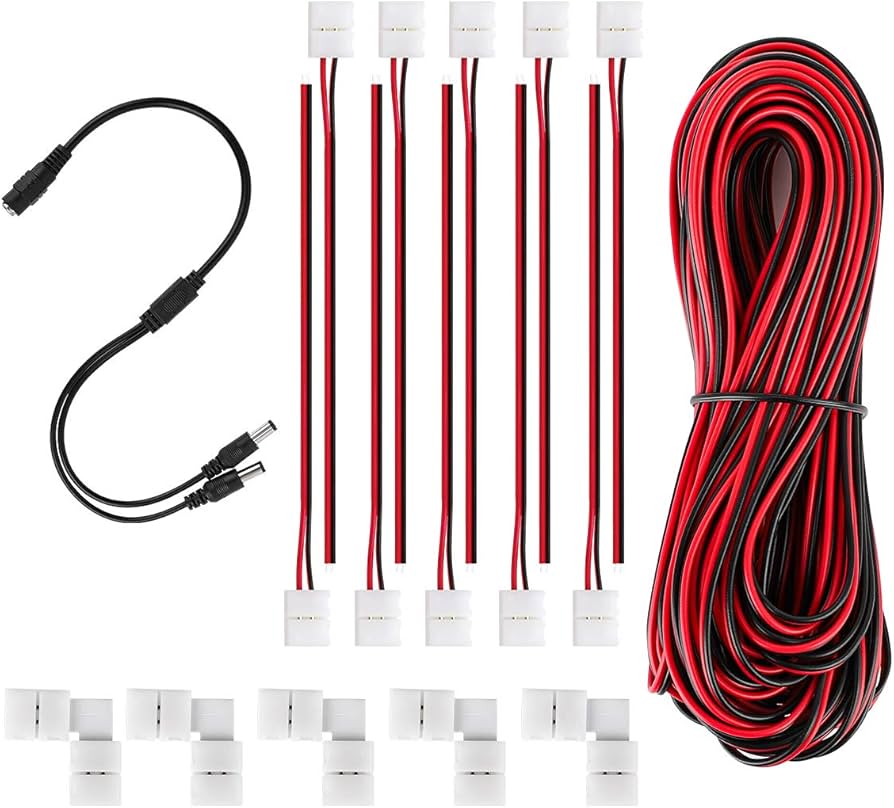

The 2-pin connector is specifically designed for single-color (monochromatic) flexible LED strip installations where simplicity, speed, and moderate reliability are priorities. It is not suitable for RGB, RGBW, or addressable LED strips which require more complex multi-pin connectors. Within commercial environments like hotels, malls, and offices, its primary applications are in low-voltage, constant-color lighting scenarios where quick assembly and disassembly for maintenance or reconfiguration are beneficial, but high IP ratings or extreme vibration resistance are not critical.

In hotels, 2-pin connectors are commonly used for indirect cove lighting in guest room ceilings or headboards, corridor accent lighting, and under-counter lighting in minibars or hospitality suites. These locations typically require discreet, low-profile connections hidden within architectural details where the connector remains protected from physical contact and moisture. The ease of disconnecting a section for bulb replacement or strip section swapping is valuable during housekeeping or room refurbishment without disturbing the entire circuit. Avoid using them in wet areas like bathrooms or exposed outdoor hotel signage where moisture ingress would compromise the connection.

Within malls and retail environments, these connectors see use in non-critical display case lighting, shelf edging for product highlighting, and some architectural cove lighting in common areas. They are practical for temporary pop-up displays or seasonal installations where fixtures are frequently reconfigured. However, exercise caution in high-traffic display zones or areas with significant temperature fluctuations; the mechanical snap-fit can loosen over time from vibration or thermal cycling, leading to intermittent connections. They are unsuitable for high-bay warehouse lighting or exterior mall facades due to inadequate environmental sealing and current limitations.

For offices, typical applications include under-cabinet task lighting in workstations or conference rooms, perimeter cove lighting in executive offices, and discreet accent lighting in reception areas. The quick-connect feature aids in modular furniture setups where lighting sections might be added or relocated during office reconfigurations. Ensure connectors are placed within accessible but concealed channels or junction boxes, never left exposed where they could be accidentally disconnected or stressed by cable movement. Avoid high-vibration zones near HVAC units or heavy machinery where the connection could fatigue.

Critical installation tips must be strictly followed to prevent premature failure. Always verify polarity meticulously before snapping the connector closed; reversing positive and negative will damage the LED strip section. Match the connector’s current rating—typically 2A to 5A per connection—to the LED strip’s actual draw, never exceeding it. For runs exceeding 2-3 meters on 12V systems, use an appropriately sized parallel feed wire directly from the power supply to the connector point to avoid voltage drop, as the connector pins themselves add resistance. Strip the wire cleanly without nicking strands and ensure bare copper fully seats into the connector terminals before clamping. After assembly, gently tug-test each connection to confirm secure retention. Finally, for any indoor application where condensation might occur (e.g., near mall food courts or climate-controlled offices), apply a small amount of dielectric grease inside the connector housing before mating to prevent corrosion, even if the connector is not rated waterproof. Always power-test the circuit before final concealment to catch polarity errors or poor connections immediately.

Why Choose Beauty STC Lighting

Looking for a reliable 2 pin connector for your LED strip project? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. Our high-quality 2 pin connectors ensure secure, durable connections for seamless LED strip installations. Engineered for performance and ease of use, they are ideal for residential, commercial, and industrial applications.

Collaborate with us to source premium components backed by years of manufacturing expertise. For inquiries or to place an order, contact us at [email protected] and let Beauty STC illuminate your next project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.