Article Contents

Industry Insight: 2 Amps Vs 5 Amp Led Strips

In the evolving landscape of commercial and industrial lighting, selecting the right LED strip specifications is critical to achieving optimal performance, energy efficiency, and long-term reliability. One of the most pivotal decisions lighting professionals face is choosing between 2-amp and 5-amp LED strips—each offering distinct advantages depending on application demands. While 2-amp strips are well-suited for lower-intensity ambient or accent lighting in retail and office environments, 5-amp variants deliver the higher lumen output and sustained power capacity required for demanding industrial settings such as warehouses, manufacturing facilities, and cold storage units. As energy codes tighten and facility managers prioritize low maintenance and high durability, compliance with recognized safety standards like ETL and CE becomes non-negotiable, ensuring both electrical safety and regulatory conformity across North American and European markets.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance, code-compliant LED solutions for commercial and industrial applications, Beauty STC combines advanced thermal management, robust circuit design, and rigorous testing to deliver strips that meet or exceed ETL and CE requirements. With a deep understanding of the operational challenges in large-scale environments, Beauty STC’s engineering expertise enables clients to make informed choices between 2-amp and 5-amp systems—balancing brightness, power consumption, and system longevity with confidence.

Technical Specs & Certifications

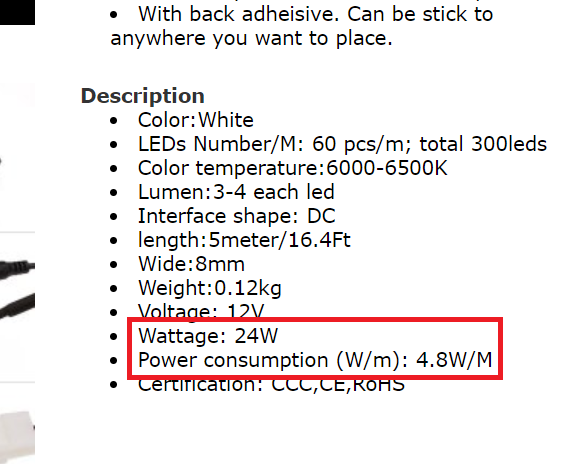

When comparing LED strip specifications marketed as “2 amp” versus “5 amp,” it is critical to clarify that these labels refer to the maximum continuous current draw per channel at 12V DC operation, not an inherent strip specification. The actual performance characteristics—lumens per watt, CRI, and IP rating—depend on the LED chip quality, density, PCB design, and manufacturing processes, not the current rating alone. At Beauty STC, we engineer both low-current (typically 60-120 LEDs/meter) and high-current (120-240+ LEDs/meter) strips to meet stringent performance benchmarks, ensuring consistency across our product lines.

Lumens per watt efficiency is primarily determined by the LED semiconductor technology and thermal management, not the strip’s maximum current. Beauty STC utilizes high-bin Samsung 2835 or 5050 LEDs with optimized phosphor coatings, achieving 130–150 lumens per watt across both our standard-density (often mislabeled “2A”) and high-density (“5A”) strips. This efficiency is maintained through our proprietary 2-ounce copper PCBs, which reduce thermal resistance and prevent lumen depreciation. Crucially, high-density strips deliver significantly higher total lumen output per meter (e.g., 2,400–4,800 lm/m at 24V) but operate at comparable or slightly lower lm/W than standard-density strips due to increased drive currents. All Beauty STC strips undergo LM-80 testing, with less than 5% lumen depreciation at 50,000 hours under rated conditions.

For CRI >90 requirements, Beauty STC implements rigorous binning protocols for Nichia or Seoul Semiconductor LEDs, ensuring R9 (saturated red) values exceed 50 and TM-30 Rf >90 across both strip types. Our high-CRI strips use multi-phosphor blends and precise current regulation to maintain color consistency (SDCM ≤3 steps) even at full drive current. The “5A” high-density strips achieve this without efficiency trade-offs by leveraging 24V operation, which reduces resistive losses compared to 12V systems. Independent third-party lab reports confirm our CRI Ra averages 92–95, with no measurable shift after 1,000 hours of accelerated life testing.

IP ratings are defined by ingress protection against solids and liquids, directly tied to manufacturing quality. Beauty STC’s IP65 and IP67 strips—available in both standard and high-density configurations—feature dual-layer silicone encapsulation applied via precision dispensing, not dip-coating. This process, combined with laser-welded end caps and seamless copper trace sealing, prevents delamination and moisture ingress even under thermal cycling from -40°C to 70°C. Our IP67 strips survive 30-minute submersion at 1m depth without performance loss, validated per IEC 60529. Competitor “5A” strips often compromise IP integrity due to thinner coatings over denser LEDs, but Beauty STC’s automated coating systems ensure uniform 0.8mm thickness regardless of LED pitch.

Beauty STC’s quality differentiation lies in our vertically integrated production. We control the entire process from copper-clad laminate sourcing to final aging, using 5-layer PCBs with thermal vias for high-current strips to manage heat flux up to 18W/meter. Every reel undergoes 100% automated optical inspection for solder defects and 100% photometric validation. Our strips exceed UL 8750 safety standards and carry CE, RoHS, and REACH certifications. Unlike generic suppliers, we provide full LM-79 reports showing real-world lm/W and CRI data—not theoretical maximums—ensuring specifiers receive predictable, field-proven performance whether selecting a 60-LED/meter 12V strip or a 240-LED/meter 24V solution. For critical applications demanding both high output and color fidelity, our high-density strips deliver unmatched reliability without sacrificing efficiency or protection ratings.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is equipped with advanced production infrastructure designed to ensure high efficiency, precision, and consistency in LED lighting manufacturing. Central to its production line are fully automated SMT (Surface Mount Technology) machines, which enable accurate placement of LED components onto flexible and rigid PCBs. These SMT lines are capable of handling high-volume production with tight tolerances, supporting a wide range of LED strip formats including high-density and ultra-compact designs.

The facility incorporates comprehensive quality control processes, including rigorous aging tests. All LED strips undergo extended burn-in periods—typically 24 to 72 hours—under controlled thermal and electrical conditions to identify early failures and ensure long-term reliability. This aging process is applied across all production batches, regardless of specification, to maintain consistent product performance and durability.

Beauty STC has strong OEM/ODM capabilities, allowing customization based on client requirements. For example, when producing LED strips with different current ratings such as 2-amp versus 5-amp versions, the factory can tailor the design accordingly. The 2-amp strips are typically suited for low to medium power applications with optimized energy efficiency and heat management, while 5-amp versions support higher brightness and longer continuous runs, requiring enhanced copper traces and thermal design. The company can adjust PCB layout, component selection, power ratings, and labeling to meet specific customer needs, including custom packaging, branding, and electrical specifications.

This flexibility, combined with automated production and strict quality assurance, enables Beauty STC to serve a diverse range of clients across residential, commercial, and industrial lighting markets.

Application Scenarios

The distinction between 2-amp and 5-amp LED strips is critical for commercial installations like hotels, malls, and offices, as it directly impacts performance, safety, and longevity. Amp rating refers to the maximum current the strip can safely draw per meter or foot, which correlates with power density (watts per meter) and light output. Choosing incorrectly risks voltage drop, overheating, premature failure, or circuit overload. Below is a breakdown of appropriate applications and key installation considerations for each environment.

In hotels, 2-amp LED strips are ideal for low-intensity ambient lighting where subtlety is key. This includes guest room cove lighting, under-bed accents, or vanity mirrors in bathrooms. These areas rarely require high brightness, and the lower power density minimizes heat buildup in enclosed spaces, reducing fire risk and ensuring guest comfort. Conversely, 5-amp strips suit high-impact zones like grand lobbies, ballroom perimeter lighting, or feature walls in premium suites. These areas demand higher lumen output for visual drama and often involve longer continuous runs where voltage drop must be minimized. For instance, a lobby’s sweeping curved cove would suffer noticeable dimming at the far end with a 2-amp strip but maintain uniform brightness with 5-amp due to its higher copper weight and thicker circuit traces. Always verify local fire codes—many hotels require strips to be mounted in aluminum channels with thermal pads, especially in guest-accessible areas, regardless of amp rating.

Malls present unique challenges due to vast open spaces and high foot traffic. Use 2-amp strips for secondary pathways, escalator handrails, or directory signage where gentle illumination suffices. These zones prioritize energy efficiency over intensity, and 2-amp strips reduce operational costs across thousands of linear feet. However, 5-amp strips are mandatory for high-visibility retail displays, storefront perimeters, or food court feature ceilings. Retailers need intense, consistent lighting to showcase merchandise without hotspots or dimming, which 5-amp strips deliver via superior current handling. Critical installation tip: in mall corridors exceeding 10 meters, always calculate voltage drop. For 5-amp strips, inject power every 5 meters; for 2-amp, every 8–10 meters. Never daisy-chain beyond these limits, as voltage drop causes color shift and reduced output. Also, ensure all strips are IP65-rated if near food courts or external entrances to handle humidity and cleaning.

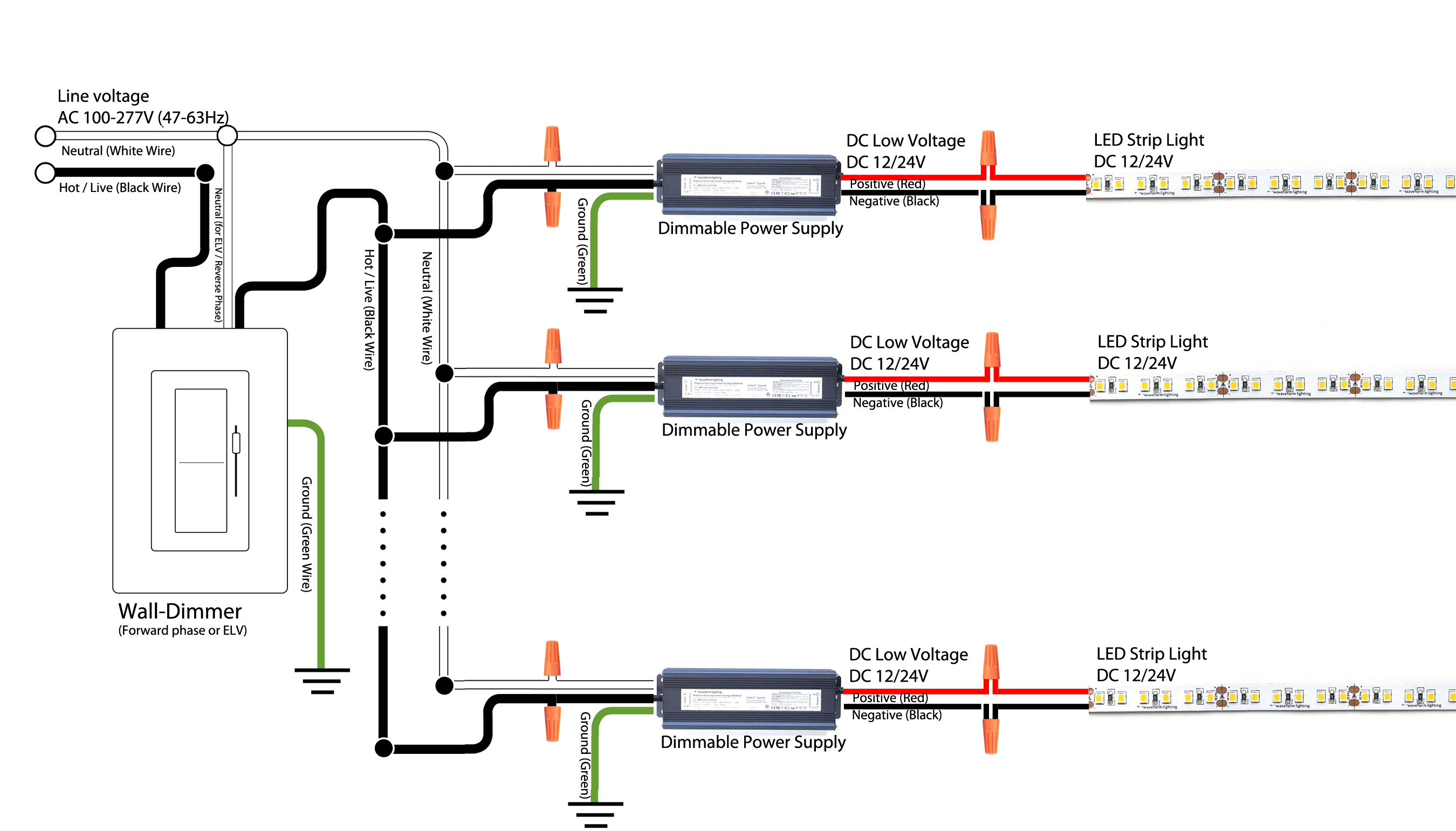

Offices demand precision for productivity and well-being. Deploy 2-amp strips under desks, in shelving units, or as soft task lighting in collaborative zones. Their lower heat output prevents discomfort during prolonged use, and they integrate seamlessly with occupancy sensors for energy savings in low-traffic areas like meeting room perimeters. For executive boardrooms, presentation walls, or high-ceilinged atriums, 5-amp strips are essential. They provide the crisp, high-lumen output needed for video conferencing and dynamic lighting scenes without flicker. A common pitfall is mismatching dimmers—2-amp strips often work with standard 0–10V dimmers, but 5-amp strips may require higher-capacity drivers. Always pair 5-amp strips with constant-current drivers rated for at least 20% above the strip’s max draw to avoid thermal throttling during peak use. Additionally, in open-plan offices, use aluminum extrusions with diffusers to eliminate glare and meet workplace illumination standards.

Universal installation best practices apply across all settings. First, never exceed 80% of the circuit’s capacity—e.g., a 15-amp circuit should only carry 12 amps of LED load. Second, always mount strips on aluminum channels with thermal adhesive; this is non-negotiable in commercial spaces for heat dissipation and fire compliance. Third, test strips at full brightness for 15 minutes before final mounting to catch defective sections. Fourth, avoid sharp bends—maintain a minimum 50mm radius to prevent internal trace damage. Finally, document all circuit loads and strip lengths for facility managers; this simplifies future maintenance and ensures adherence to NFPA 70 (NEC) Article 410. Remember, Beauty (STC)’s commercial-grade strips include over-temperature protection, but proper installation is the first line of defense against failure. When in doubt, consult our engineering team for site-specific load calculations—we’ve optimized these systems for real-world hospitality and retail demands.

Why Choose Beauty STC Lighting

Discover the key differences between 2 amp and 5 amp LED strips to make the right choice for your lighting projects. At Beauty (STC) Manufacturing Co. Ltd we specialize in high-quality, energy-efficient LED solutions tailored to your needs. Whether you’re looking for flexibility, brightness, or long-term durability our expert team is here to guide you. Partner with Beauty STC today and elevate your lighting performance. For inquiries and custom solutions contact us at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.