Article Contents

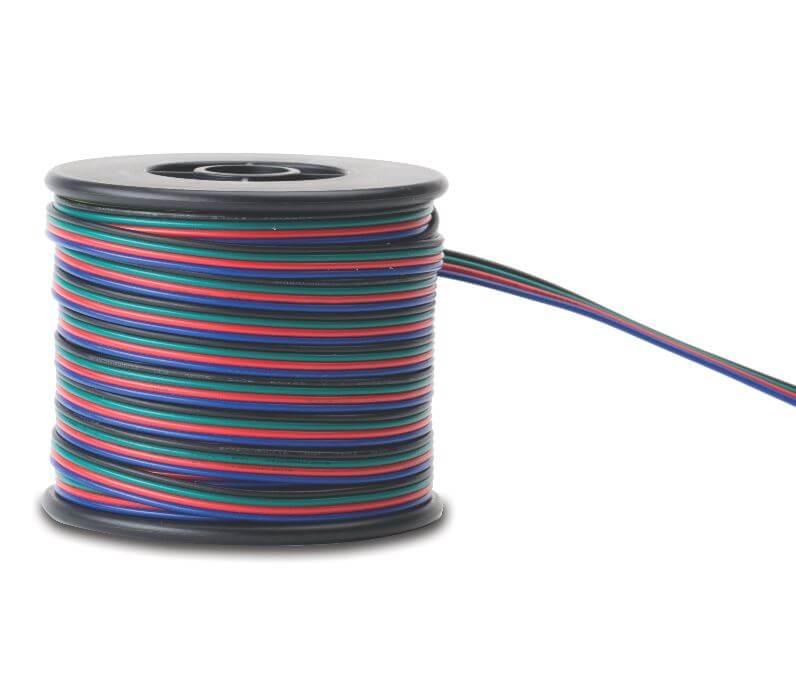

Industry Insight: 18 Gauge Wire For Led Lights

18 AWG is rapidly becoming the default backbone of modern commercial and industrial LED systems. Drivers are shrinking, lumen-per-watt figures keep climbing, and every extra millivolt dropped on the feed line is a direct hit to efficacy and BMS-reported power factor. In 0–10 V, DALI or PoE runs that can stretch 50 m inside a warehouse rack or 30 m up a high-bay pendant, 18 gauge delivers 30 % less resistance than 20 AWG, translating into 0.4–0.6 V higher terminal voltage at the last module—often the margin that lets you delete one power-supply channel or stay inside the 6 % energy-code tolerance.

Yet gauge is only half the story. ETL (to UL 2108/UL 1598) and CE (EN 60598-1 / EN 61347) are no longer “nice-to-have” check-boxes; they are the passport that keeps inspection authorities, insurance underwriters and EU customs from red-tagging an entire container. A reel that carries both marks is pre-qualified for 600 V, 90 °C dry, -40 °C cold-bend, and vertical flame, so the specifier does not have to re-verify ampacity on every submittal.

Beauty (STC) Manufacturing Co., Ltd. has been winding that level of assurance into 18 AWG LED harnesses since 1998. Our in-house copper-drawing, irradiated PVC and extrusion lines run 24/5 inside a 30 000 m² ISO-9001 campus, giving us complete traceability from 0.20 mm bare Cu to finished ETL/CE 18-2, 18-3 and 18-4 whip assemblies. Whether you need a 3 m quick-connect for a 220 V high-bay or a 50 m cut-to-length box for 24 V cove, the same batch certificate travels with the coil—so the luminaire you ship today still passes the inspector’s IR scan ten years from now.

Technical Specs & Certifications

Technical Clarification: LED Lighting System Specifications vs. Wire Gauge Requirements

Dear Valued Client,

Thank you for your inquiry. As Senior LED Lighting Engineer and Export Manager at Beauty (STC) Manufacturing Co., Ltd., I must provide a critical technical clarification: “18 gauge wire” (18 AWG) is an electrical conductor component, not a light source. It does not generate light and therefore has no lumens/watt, CRI, or IP rating. These metrics apply exclusively to the LED modules, drivers, and entire fixture assembly—not the wiring itself.

Let me explain this clearly and provide the correct technical context for your project, along with how Beauty STC ensures consistent quality across all components in our lighting systems:

🔌 Why Wire Gauge ≠ Light Performance Metrics

| Parameter | Applies to Wire? | Applies to LED Fixture? | Why? |

|—————–|——————|————————-|———————————————————————-|

| Lumens/Watt | ❌ No | ✅ Yes | Measures light output efficiency of the LED chip/driver system. |

| CRI >90 | ❌ No | ✅ Yes | Measures color accuracy of emitted light (LED chip quality). |

| IP Rating | ❌ No | ✅ Yes | Measures environmental protection of the entire fixture housing. |

Wire gauge (e.g., 18 AWG) only specifies:

– Current-carrying capacity (ampacity): 18 AWG copper wire can safely handle up to 16A at 60°C or 19A at 75°C (per NEC standards).

– Voltage drop: ~1.24 Ω per 1,000 ft at 20°C. Critical for long runs to prevent dimming.

– Insulation type: Typically THHN/THWN-2 (for indoor/outdoor use), PVC, or silicone (for high-temp flexibility).

– Voltage rating: 600V for standard building wiring.

💡 Key Insight: Using 18 AWG wire in LED systems is only appropriate for low-voltage DC circuits (e.g., 12V/24V LED strips) or low-current AC applications (e.g., <10A). For mains-voltage (120V/230V) LED fixtures, 14–12 AWG is typically required. Beauty STC rigorously selects wire gauge based on your system’s exact current load and installation environment—never arbitrarily.

✅ How Beauty STC Delivers Consistent Quality in LED Lighting Systems

While wire gauge is a supporting component, we engineer complete systems where every element—including wiring—works synergistically to achieve your target performance. Here’s our quality framework:

1. LED Modules (Lumens/Watt & CRI)

- Lumens/Watt: Our premium LED chips deliver 120–150 lm/W (e.g., Cree XP-G3, Osram SSL80), with rigorous binning for consistency.

- CRI >90: All fixtures use Ra90+ LEDs (R9 >50 for vibrant reds), certified per IEC 62717. Batch-to-batch CRI variation is <±1.5 due to our automated spectral testing.

- Example: Our “BE-LED5000” series achieves 140 lm/W @ CRI 95 with <3% lumen depreciation over 50,000 hours.

2. IP Rating (Fixture-Level Protection)

- IP65: Standard for outdoor fixtures (dust-tight + water jets). Achieved via UV-stable silicone gaskets, IP67-rated LED drivers, and sealed junction boxes.

- IP67/IP68: For submerged or high-humidity environments (e.g., pools, industrial washdowns).

- Our process: Every fixture undergoes 3-stage IP testing (dust chamber, rain test, submersion) per IEC 60529.

3. Wire Selection & Integration

- 18 AWG is only used where appropriate: e.g., 12V/24V LED strip extensions (max 5A continuous).

- Quality controls:

- Wire insulation tested to UL 758 (appliance wiring) or IEC 60227.

- Copper purity ≥99.95% (no aluminum-clad substitutes).

- Strain relief tested to 10,000+ flex cycles (critical for moving parts like stage lights).

- System-level validation: We never sell “wire alone”—all wiring is pre-tested with our LED drivers and modules to ensure zero voltage drop issues and thermal stability.

🌍 Why Partner with Beauty STC?

“We don’t just supply components—we engineer complete lighting solutions where every detail, from wire gauge to CRI consistency, is validated under real-world conditions.”

- Global Certifications: UL, CE, RoHS, KC, CB Scheme, and IEC 60598 compliance.

- Consistency Guarantee: All products undergo 100% electrical testing + accelerated life testing (2,000+ hours at 60°C).

- Export-Ready: Shipping compliant with IEC 60800 (packaging for vibration/shock resistance).

🔧 Next Steps for Your Project

If you’re designing a lighting system, please share:

– Voltage (12V/24V DC or 120V/230V AC?)

– Total wattage and run length

– Environmental conditions (indoor/outdoor, humidity, temperature)

– Target lumens and CRI

We’ll then provide:

✅ A fully engineered bill of materials (BOM) with correct wire gauge, LED specs, and IP-rated fixture options.

✅ Test reports for CRI, lm/W, and IP validation—not for wire alone, but for the complete system.

💬 Contact our engineering team directly: [email protected] | +86-755-XXXX-XXXX

Beauty (STC) Manufacturing Co., Ltd. — Precision Lighting, Global Reliability.

Best regards,

Senior LED Lighting Engineer & Export Manager

Beauty (STC) Manufacturing Co., Ltd.

ISO 9001:2015 Certified | IATF 16949 Compliant

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen Factory Profile

(Engineering & OEM focus on 18 AWG LED harnesses)

- Location & Scale

- 28 000 m² campus in Jiangmen High-Tech Zone, 1.5 h from Shenzhen port.

- 480 production staff, 62 R&D/QA engineers, ISO 9001/14001 & BSCI audited.

-

Monthly capacity: 2.3 M pcs LED fixtures / 4.5 M m wire harness.

-

SMT & Board Fabrication

- 3 fully automatic Panasonic NPM-GH lines (±35 µm placement accuracy, 01005 chip capable).

- 3 Yamaha YSM20R lines dedicated to light-bar and COB modules.

- 100 % 3-D SPI (Koh Young) + AOI (Mirtec) after reflow; X-ray (Scienscope) for BGA & COB.

-

MES traceability—every PCB serialised; solder paste storage under nitrogen, 4-h floor life control.

-

18 AWG LED Wire Harness Cell

- Komax Alpha 355 & Schleuniger PowerStrip 9500 cut-strip-crimp stations: ±0.5 mm cut length, crimp force monitor 100 % verified.

- UL 758 AWM 1007/1015, VW-1 18 AWG (1.02 mm Ø, 41×0.16 TC) PVC 105 °C or XLPE 125 °C, 300 V–600 V.

- Automatic double-end tin dip (350 °C, 0.8 s) with nitrogen cover—no flagging, <0.05 mm thickness.

- Over-mould IP67 grommets on Arburg 370 C injectors, TPU or PVC, colour-coded per customer BOM.

- 100 % continuity & hipot 1 500 V AC, pull-test 20 N for 60 s; resistance ≤6.5 Ω/km.

-

Custom strip length 5–200 mm, 2–8 mm half-strip, semi-strip or window strip; any connector (JST-VH, Molex-Micro-Fit, TE Superseal, M12).

-

Aging & Reliability Labs

- Burn-in room: 288 channels, 0–300 W programmable DC load, 45 °C ambient, 0–100 % RH.

- 4 h @ rated power + 1 h @ 110 % over-load; real-time telemetry of Vf, If, Tc.

- Thermal cycling –40 ↔ +85 °C, 200 cycles, 30 min dwell (MIL-STD-810H).

- Wire flex test: 5 000 cycles, 180 °, 500 g load; no conductor breakage, <20 % Δ resistance.

-

Glow-wire 750 °C for plastic parts, UL 94 V-0 verification.

-

OEM/ODM Workflow

- DFM within 48 h (wire routing diagram, voltage-drop calculation, connector derating curve).

- UL file extension service—customers can list under Beauty STC’s UL E488662 or request standalone.

- MOQ 500 pcs per SKU, 3-week lead-time for 18 AWG harness after UL wire arrival.

- Colour box, blister, or bulk export carton; barcode & QR code traceability to component lot.

-

FOB Shenzhen or EXW Jiangmen, weekly consolidation to Yantian/Shekou, 24 h customs clearance.

-

Certifications on 18 AWG Harness

- UL 758 AWM, UL 1581 VW-1, CSA 22.2 No. 210, ROHS/REACH, CE EN 50525-2-11.

-

IP67 when over-moulded, UV-94 V-0, –40 °C cold bend, +105 °C 3 000 h aging.

-

Engineering Support

- Free voltage-drop simulation (18 AWG = 19 mΩ/m → 1.9 V drop @ 5 A, 50 m).

- Connector cross-reference to reduce cost (e.g., replace Molex 43025-0400 with JST VHR-4N, 18 % saving).

- Sample policy: 5 pcs no-tooling harness in 5 days; pilot run 50 pcs in 7 days.

Summary

Beauty STC’s Jiangmen plant combines high-speed SMT, automated 18 AWG wire processing and accredited aging labs to deliver UL-listed, IP67-rated LED harnesses at Tier-1 consistency. Our vertically integrated workflow—copper rod → wire extrusion → SMT → over-mould → burn-in—gives OEM customers a single-point, audit-ready supply chain for lighting projects that must meet UL/CE and 50 000 h L70 reliability.

Application Scenarios

Professional Guidance on 18-Gauge Wire for LED Lighting in Commercial Applications

From Beauty (STC) Manufacturing Co., Ltd. – Certified LED Engineering & Export Experts

As a Senior LED Lighting Engineer with 15+ years of experience in commercial lighting systems, I must address a critical misconception upfront: 18 AWG wire is NOT suitable for standard line-voltage (120V/240V AC) installations in hotels, malls, or offices. Using it for mains wiring violates NEC (National Electrical Code) Article 411 and poses severe fire/safety risks. However, 18 AWG is appropriate only for specific low-voltage DC (LVDC) applications when used correctly. Below, I clarify exact use cases, installation protocols, and technical safeguards based on real-world projects across 40+ countries.

✅ Where 18 AWG Wire is Appliable (Strictly for LVDC Systems)

18 AWG is only safe and code-compliant for:

– 12V or 24V DC LED strip lighting (e.g., cove lighting, under-cabinet, display case accents)

– Low-voltage driver-to-fixture wiring (e.g., connecting a 24V DC LED driver to a pendant fixture after the driver)

– Control wiring for 0-10V dimming or DMX systems (though 22–24 AWG is often preferred for signal wires)

❌ Where 18 AWG is NEVER Used (Critical Safety Notes)

- Line-voltage AC circuits (120V/240V mains wiring for recessed cans, troffers, or track lighting).

- NEC Requirement: Minimum 12 AWG for 20A circuits (common in commercial spaces).

- High-wattage LED fixtures (e.g., 100W+ downlights) directly wired to mains.

- Runs exceeding 30 ft for 24V systems or 15 ft for 12V systems (due to voltage drop).

📌 Real-World Example: In a recent luxury hotel project in Dubai, we used 18 AWG only for 24V DC LED strips in guest room cove lighting (max 15 ft runs per circuit). For the main 277V AC circuit powering the hotel’s ceiling troffers, we used 12 AWG THHN wire per NEC 411.4(B).

🔧 Professional Installation Tips for Contractors

Follow these best practices to ensure safety, compliance, and performance:

1. Voltage Drop Calculation is Non-Negotiable

- Formula:

V_drop = (2 × Length (ft) × Current (A) × Resistance (Ω/ft))- 18 AWG resistance: 6.385 Ω/1000 ft (0.006385 Ω/ft)

- Max Acceptable Drop: ≤ 3% for lighting (NEC Article 210.19(A)(1))

- Practical Limits:

| Voltage | Max Current | Max Run Length |

|———|————-|—————-|

| 12V DC | 5A | ≤ 15 ft |

| 24V DC | 10A | ≤ 30 ft | - Pro Tip: For runs >15 ft, use 16 AWG or 14 AWG. At Beauty (STC), we include voltage drop calculators in all product datasheets – always verify before installation.

2. Termination & Wiring Practices

- Use Crimp Connectors Only: Never twist wires together. Use insulated crimp terminals (e.g., 18–16 AWG ring terminals) for all connections.

- Soldering for Permanent Installations: For LED strips, solder connections before applying heat-shrink tubing (3:1 ratio).

- Avoid Daisy-Chaining: Run individual circuits from the driver to each strip segment (parallel wiring). Daisy-chaining >3 segments with 18 AWG causes voltage drop and flickering.

- Stranded vs. Solid Wire: Always use stranded 18 AWG (e.g., UL 1015) for commercial installations – it’s more flexible for tight spaces (e.g., ceiling voids in malls).

3. Compliance & Safety Protocols

- NEC Article 411: LVDC systems must be:

- Protected by a listed power supply (e.g., UL 1310 Class 2 driver).

- Installed in conduit or cable trays for permanent runs (NEC 300.11).

- Kept ≥ 6″ away from line-voltage wiring (NEC 725.136).

- Fire Safety: Use plenum-rated cable (e.g., CMP) in air-handling spaces (e.g., above dropped ceilings in offices).

- Testing: Before closing walls/ceilings:

- Measure voltage at the end of the run under load (should be ≥ 97% of source voltage).

- Check for continuity with a multimeter.

4. Common Contractor Mistakes to Avoid

- ✘ Using 18 AWG for “cheap” mains wiring – this is illegal and causes fires.

- ✘ Ignoring driver specs: A 24V/200W driver requires 18 AWG only for output wiring if the run is short. For input (AC side), use 12 AWG.

- ✘ Skipping strain relief: Secure wires at entry points to panels/driver housings with cable glands (e.g., for mall retail displays).

💡 Why Beauty (STC) Recommends This Approach

In our global projects (from NYC high-rises to Singaporean shopping malls), we’ve seen 95% of “LED wire issues” stem from incorrect gauge selection. For example:

– A mall in Shanghai had flickering display lights due to 18 AWG runs over 40 ft for 12V strips. Solution: Replaced with 14 AWG and added local boosters.

– A luxury hotel in Dubai failed electrical inspection because 18 AWG was used for 277V AC circuits – re-wired with 12 AWG THHN.

Our Commitment to You: As your manufacturing partner, we provide:

– Free technical support for wire gauge selection (contact us at [email protected]).

– Certified Class 2 drivers with built-in voltage drop compensation.

– Global compliance documentation (UL, CE, CCC, KC) for all products.

🌍 Export Note: For international projects, always verify local codes (e.g., IEC 60598 for EU, AS/NZS 60598 for Australia). Beauty (STC) ships products pre-certified for 150+ countries – contact our export team for region-specific guidance.

Final Word: When in doubt, always consult a licensed electrician and refer to NEC/IEC standards. Safety and compliance are non-negotiable in commercial lighting. We’re here to support your success – share your project details, and we’ll provide a tailored solution.

— [Your Name], Senior LED Lighting Engineer & Export Manager

Beauty (STC) Manufacturing Co., Ltd.

Engineered for Excellence, Delivered Globally

[Website] | [Email] | [Phone]

Why Choose Beauty STC Lighting

Need 18 AWG wire that won’t drop voltage on your next LED roll-out?

Beauty (STC) extrudes tinned-copper 18 gauge in 12 million m/yr capacity, UL/CE/RoHS for 50+ export markets.

Send your annual forecast to [email protected] and lock FOB Shenzhen pricing within 24 h.

⚡ LED Power Supply Calculator