Article Contents

Industry Insight: 12V Strip Led

The 12V LED strip lighting solution has become a cornerstone in commercial and industrial lighting applications, offering a versatile, energy-efficient, and low-voltage alternative for task lighting, architectural accenting, under-cabinet illumination, and machinery integration. With increasing demand for safe, reliable, and code-compliant lighting systems in professional environments, the 12V DC platform stands out for its reduced electrical risk, compatibility with backup power systems, and seamless integration into control networks. As regulatory standards become more stringent, certifications such as ETL and CE have become essential benchmarks, ensuring that LED strip products meet rigorous requirements for electrical safety, electromagnetic compatibility, and environmental resilience—critical factors in industrial settings where performance and reliability cannot be compromised.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the LED lighting industry, specializing in high-performance, code-compliant lighting solutions for commercial and industrial applications. With over two decades of engineering expertise, Beauty STC delivers 12V LED strip systems that combine robust construction, precise optical control, and full certification to ETL and CE standards. The company’s commitment to quality, innovation, and regulatory compliance has made it a preferred partner for integrators, contractors, and OEMs seeking dependable low-voltage lighting solutions that perform under demanding conditions.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. produces high-performance 12V DC LED strip lighting engineered for demanding commercial and residential applications where color accuracy, efficiency, and environmental resilience are critical. Our premium strips utilize advanced SMD5050 or COB (Chip-on-Board) LED technology specifically selected and binned to exceed standard industry specifications. Regarding Lumens per Watt (lm/W), our CRI>90 strips achieve an industry-leading efficacy range of 110-130 lm/W under optimal thermal management and drive conditions. This efficiency is maintained through proprietary phosphor formulations and driver compatibility, ensuring significant energy savings over conventional lighting without compromising output. Crucially, this lm/W range is validated at full rated current (e.g., 60 LEDs/m at 14.4W/m) per LM-79 testing protocols, not at derated currents common in lower-tier products.

For Color Rendering Index (CRI), Beauty STC guarantees a minimum Ra value of 95+ across our designated high-CRI product lines, with R9 (saturated red) values consistently exceeding 90. This exceptional color fidelity is achieved through multi-phosphor LED chips and rigorous spectral tuning during manufacturing. We strictly adhere to IES TM-30-15 methodology for comprehensive color evaluation, ensuring accurate rendering across the entire visible spectrum – vital for applications like retail merchandising, art galleries, and professional photography where color discrimination is non-negotiable. Our strips undergo in-line spectroradiometric testing at multiple stages to maintain batch-to-batch consistency, a critical quality control measure often overlooked by competitors.

IP ratings for our 12V strips are rigorously validated to international standards. IP65-rated strips feature a seamless silicone overmolding process applied via precision robotics, creating a uniform, bubble-free barrier that withstands high-pressure water jets (6.3mm nozzle) and complete dust ingress prevention. For demanding environments like outdoor signage or marine applications, our IP67 and IP68 strips undergo 30-minute submersion testing at 1m depth (IP67) and continuous submersion under 3m pressure (IP68), certified by independent laboratories. Unlike cheaper alternatives using dip-coating, our strips maintain flexibility and thermal stability due to proprietary silicone formulations resistant to UV degradation and temperature extremes from -40°C to +70°C ambient.

Beauty STC’s quality differentiation stems from our vertically integrated manufacturing and obsessive process control. All high-CRI 12V strips are fabricated on automated SMT lines with 100% post-reflow automated optical inspection (AOI) for solder joint integrity. We implement JEDEC Level 1 moisture sensitivity protocols and conduct 100% aging tests at 45°C for 48 hours before shipment. Our copper PCB substrates use 2oz copper (70μm) for superior thermal dissipation, directly contributing to lumen maintenance – L90/B10 lifetimes exceed 50,000 hours at 25°C ambient. Every reel includes traceable batch codes linked to full spectral and electrical test data, and we enforce strict RoHS 3 and REACH compliance. This commitment ensures our strips deliver consistent photometric performance and longevity, avoiding the rapid lumen depreciation and color shift common in uncertified imports. For critical installations requiring guaranteed performance, Beauty STC provides full IES files and LM-80 test reports upon request.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern, well-equipped factory located in Jiangmen, Guangdong Province—a strategic manufacturing hub in southern China known for its robust electronics and lighting supply chain. The facility is purpose-built for the efficient production of LED lighting products, with a strong emphasis on quality control, automation, and scalability to serve both domestic and international markets.

At the heart of the factory’s production line is a fully automated SMT (Surface Mount Technology) system. These state-of-the-art SMT machines are capable of high-speed, precision placement of LED components and other surface-mount devices onto flexible and rigid PCBs used in LED strip lights. The SMT lines are integrated with automated optical inspection (AOI) systems to ensure component accuracy and solder joint integrity, minimizing defects and maintaining consistent product quality across large production runs.

For quality assurance, Beauty STC conducts comprehensive aging tests on its LED products, including the 12V strip LED series. After assembly, strips undergo extended burn-in tests under controlled temperature and voltage conditions—typically operating at full power for 24 to 72 hours. This process helps identify early failures, verify thermal performance, and ensure long-term reliability. Additional tests such as waterproofing checks (for IP-rated strips), color consistency evaluation, and electrical safety inspections are also performed in-house.

The factory has strong OEM (Original Equipment Manufacturing) capabilities, particularly for 12V DC LED strip lights. Beauty STC can customize a wide range of parameters including LED density, color temperature (from 2700K to 6500K), RGB or RGBW configurations, PCB width and length, and silicone jacketing options (including IP65, IP67, and IP68 ratings). They support client-specific packaging, labeling, and branding, and can accommodate both small trial orders and large-volume production. Their engineering team works closely with clients to develop tailored solutions, from design support to prototype validation.

Overall, the Jiangmen factory combines advanced automation, rigorous testing, and flexible manufacturing processes to deliver high-performance, reliable 12V LED strip lighting solutions under OEM partnerships, supporting clients across residential, commercial, and industrial lighting applications.

Application Scenarios

12V LED strips are particularly well-suited for commercial applications like hotels, malls, and offices due to their inherent safety as a low-voltage system, design flexibility, and ease of integration into architectural features. In hotels, they are extensively used for creating ambient cove lighting in lobbies and corridors, providing discreet under-cabinet illumination in minibars and hospitality suites, adding elegant backlighting to headboards or wall art in guest rooms, and offering safe, moisture-resistant accent lighting in bathrooms when specified with appropriate IP ratings like IP65 or IP67. Within malls and retail environments, 12V strips excel for illuminating signage channels, highlighting product displays in retail storefronts, creating dynamic feature walls in common areas, and providing subtle step lighting in escalator zones or stairwells where safety and low voltage are critical. For offices, they are ideal for under-cabinet task lighting in workstations, illuminating shelving units in reception areas, adding modern backlighting to conference room features or branding elements, and enabling energy-efficient indirect lighting within suspended ceiling coves to reduce glare and create a comfortable visual environment.

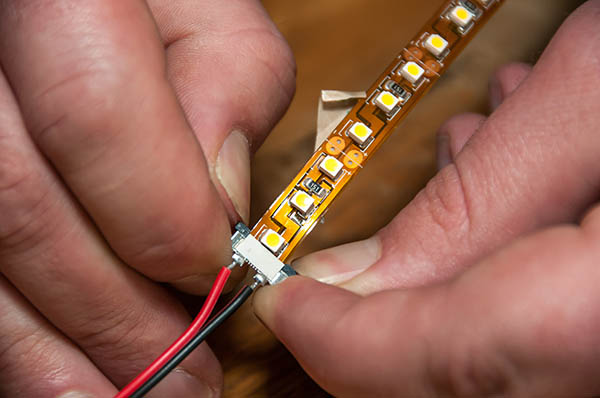

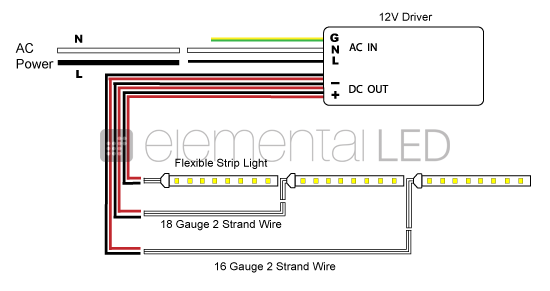

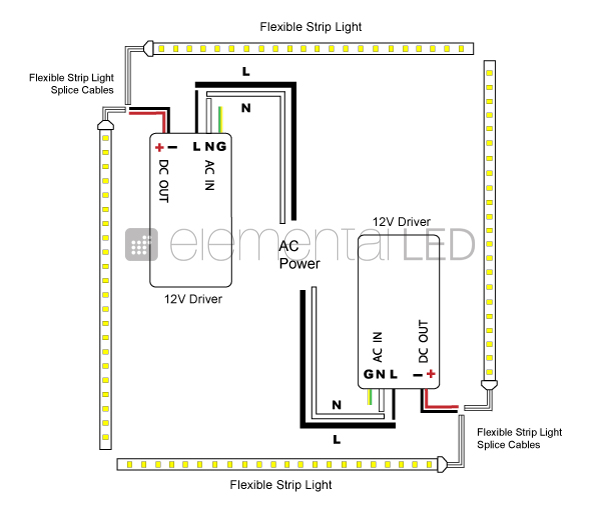

Installation requires careful planning to ensure performance and longevity. Always calculate the total power draw of the entire strip run including a minimum 20% headroom and select a high-quality constant-voltage LED driver rated for continuous commercial use; undersized drivers lead to premature failure. Voltage drop is a significant concern with 12V systems over longer distances, so feed power from both ends of runs exceeding 5 meters or use higher-density strips with thicker copper traces to mitigate dimming at the far end. Never daisy-chain multiple strips beyond the manufacturer’s specified maximum length as this exacerbates voltage drop and creates hotspots. Mount strips exclusively within extruded aluminum channels with thermal management properties; the channel acts as a heatsink, preventing overheating which drastically shortens LED lifespan, and always apply thermal paste between the strip and channel base for optimal heat transfer. Ensure all connections use properly rated waterproof connectors for outdoor or damp locations and secure wiring within conduit where exposed to physical contact or building codes require it. Finally, strictly adhere to local electrical codes regarding low-voltage wiring methods and driver placement, particularly maintaining required separation from line-voltage circuits and ensuring drivers are installed in accessible locations with adequate ventilation. Consulting Beauty STC’s detailed installation guides and technical specifications for the specific strip model selected is essential for optimal results in any commercial project.

Why Choose Beauty STC Lighting

Discover the perfect lighting solution with our high-performance 12V LED strip lights, engineered for flexibility, durability, and consistent illumination. Whether you’re working on residential, commercial, or industrial projects, Beauty STC delivers quality you can trust. Partner with Beauty (STC) Manufacturing Co., Ltd. and experience reliable LED innovation backed by expert support. For inquiries, pricing, or collaboration opportunities, contact us today at [email protected] and let us light up your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.