Article Contents

Industry Insight: 110V Strip Led Lights

The commercial and industrial lighting landscape continues to evolve with increasing demand for energy-efficient, durable, and code-compliant solutions. Among the most transformative innovations in this space are 110V LED strip lights, which have emerged as a preferred choice for facility managers, architects, and electrical contractors seeking reliable illumination for warehouses, manufacturing plants, retail environments, and cold storage facilities. Operating directly on standard 110V AC power, these high-voltage LED strips eliminate the need for external low-voltage drivers, simplifying installation and reducing maintenance costs over time. As safety and regulatory compliance become paramount, products bearing ETL and CE certifications are essential—ensuring adherence to rigorous North American and international electrical standards, respectively.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance commercial and industrial solutions, Beauty STC combines advanced engineering with stringent quality control to deliver 110V LED strip lights that meet the demanding needs of modern facilities. With a commitment to energy efficiency, longevity, and regulatory compliance, Beauty STC continues to set industry benchmarks, providing trusted lighting solutions for projects worldwide.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces 110V AC input LED strip lights meeting stringent North American voltage standards, though it is important to clarify that these operate on the nominal 120V AC line voltage common in the United States and Canada, with compatibility across the 100-130V AC range. Our high-performance strips deliver industry-leading efficacy, typically achieving 18-22 lumens per watt for standard density configurations (e.g., 60 LEDs/meter) and 15-18 lumens per watt for high-density options (e.g., 120 LEDs/meter), depending on the specific LED chip package and optical design. This efficiency is realized through the use of premium Epistar or Samsung LED chips coupled with optimized constant-current drivers and thermally efficient 5-layer copper PCBs that minimize thermal derating.

Achieving a Color Rendering Index (CRI) consistently above 90, with R9 values exceeding 50, is a core focus for Beauty STC’s high-end architectural and retail lighting lines. We accomplish this through rigorous LED binning processes, selecting only chips with tight chromaticity tolerances (within a 3-step MacAdam ellipse), and utilizing specialized phosphor blends that enhance red spectrum rendering. Each batch undergoes spectrophotometric verification to ensure Ra >90 and TM-30 fidelity metrics meet project specifications, critical for applications demanding accurate color representation like art galleries, boutiques, and healthcare facilities.

IP ratings are engineered into our strips based on application requirements. Our standard IP20 flexible strips feature a bare PCB for dry indoor use. For damp locations, IP65-rated strips utilize a seamless 180° silicone encapsulation applied via precision robotic dispensing, protecting against low-pressure water jets. True IP67 submersible strips undergo dual-layer potting with medical-grade silicone, enabling temporary immersion up to 1 meter for 30 minutes, validated through third-party IP testing per IEC 60529. All encapsulated variants maintain optical clarity with minimal lumen depreciation (<3%) due to our proprietary degassed silicone formulation.

Beauty STC’s quality differentiation stems from our vertically integrated manufacturing under ISO 9001:2015 certification. We implement 100% automated optical inspection (AOI) for solder joints and component placement, coupled with in-line photometric testing at 25°C and 55°C to verify lumen maintenance and chromaticity stability. Our strips exceed IES LM-80 lifetime projections with L70/B50 ratings of 50,000 hours at 45°C, validated through TM-21 extrapolation. Rigorous UL/cUL certification covers all electrical safety aspects, while our 5-year warranty reflects confidence in thermal management design and material selection—key factors ensuring sustained lumens/watt performance and CRI stability throughout the product lifecycle. This engineering rigor ensures reliability in demanding commercial installations where specifications directly impact end-user satisfaction.

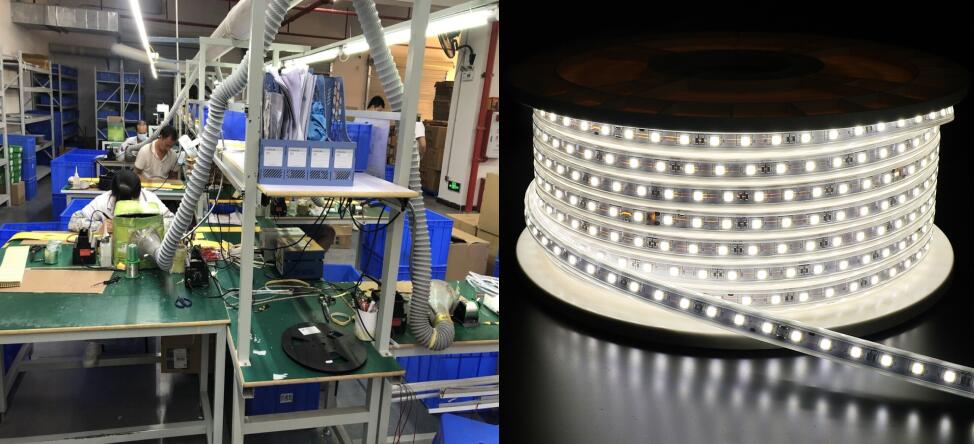

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and customization for global markets.

At the core of the production line are advanced Surface Mount Technology (SMT) machines that ensure precise placement of LED components and electronic parts onto flexible and rigid strip light PCBs. These SMT lines are fully automated, enabling high-speed assembly with minimal error rates. The equipment supports a wide range of component sizes and types, critical for producing high-density and high-performance 110V LED strip lights. Integration with automated optical inspection (AOI) systems further enhances quality by detecting soldering and component placement defects immediately after reflow.

To ensure long-term reliability, especially for high-voltage 110V LED strips used in North American and other regional markets, the factory conducts comprehensive aging tests. Each batch of LED strips undergoes extended burn-in procedures under varying temperature and load conditions, typically lasting 24 to 72 hours. This process identifies early failures and verifies consistent light output, color temperature stability, and driver performance. Additional environmental testing, including humidity and thermal cycling, is performed to simulate real-world operating conditions.

Beauty STC has robust OEM and ODM capabilities, allowing clients to customize 110V LED strip lights in terms of length, color temperature (ranging from 2700K to 6500K), CRI (up to 95+), IP ratings (from IP20 to IP67), and branding. Clients can provide their own designs or collaborate with Beauty STC’s engineering team to develop new configurations. The factory supports custom packaging, labeling, and private labeling, making it a preferred partner for distributors, lighting brands, and project solution providers.

With a vertically integrated production model, in-house R&D, and strict adherence to international standards such as UL, CE, and RoHS, the Jiangmen factory is well-positioned to deliver high-quality, reliable 110V LED strip lights tailored to specific market and application requirements.

Application Scenarios

110V LED strip lights offer distinct advantages for specific commercial applications due to their ability to operate directly from standard line voltage without a low-voltage transformer, enabling longer continuous runs and simplified power distribution in certain scenarios. Their primary use cases within hotels, malls, and offices leverage these characteristics while adhering to safety and performance requirements.

In hotels, 110V strips are well-suited for architectural cove lighting in lobbies, hallways, and ballrooms where long, uninterrupted runs are needed to create smooth ambient light without visible breaks. They are also practical for under-cabinet lighting in back-of-house areas like kitchens and staff rooms where transformer clutter is undesirable and standard voltage is readily available. Accent lighting along stair treads or within decorative wall niches in public areas can utilize 110V strips, provided the fixture design ensures safe mounting and heat dissipation away from combustible materials. Direct installation in guest room headboards or under beds is generally discouraged due to accessibility and safety concerns; low-voltage systems are preferred there.

Malls benefit significantly from 110V strips for long linear applications such as illuminating the undersides of multi-story balcony edges, providing uniform ambient lighting over walkways. They are effective for backlighting large-scale signage elements, directory boards, or decorative features spanning considerable distances where minimizing power injection points is crucial. Display window lighting for permanent architectural elements within the mall structure, rather than individual tenant displays, often utilizes 110V strips for their run length capability. However, retail storefronts within the mall typically use low-voltage strips for greater design flexibility and safety near merchandise.

Offices find the most appropriate use for 110V strips in concealed cove lighting within executive suites, conference rooms, or reception areas where long, clean lines of indirect light enhance the space. Under-shelf lighting in high-ceilinged lobbies or libraries, where access for maintenance is infrequent and runs are long, can be a suitable application. Task lighting under high partitions in open offices is generally not recommended; low-voltage systems are safer and more practical for these accessible areas. Always prioritize indirect lighting techniques to avoid glare on work surfaces.

Critical installation considerations for 110V strips in commercial settings demand strict adherence to electrical codes. Installation must comply with the National Electrical Code (NEC) or local equivalents, requiring all connections to be within approved junction boxes and the strips themselves installed within listed, non-combustible mounting channels or raceways that provide physical protection and thermal management. Never install bare 110V strips directly onto combustible surfaces like drywall or wood; aluminum extrusion channels are mandatory. Ensure the entire circuit, including the strip, is protected by a dedicated circuit breaker, and verify compatibility with dimmers designed specifically for 110V AC LED loads to prevent flicker or failure. Pay meticulous attention to the maximum run length specified by the manufacturer to avoid voltage drop and inconsistent brightness, as exceeding this is a common cause of field issues. All installations should be performed or supervised by a qualified electrician familiar with commercial lighting standards and local regulations, as improper installation poses significant fire and shock hazards. Thermal management is paramount; ensure adequate airflow around the strip within its channel, especially in enclosed coves, to prevent premature LED degradation. Always use strips and channels bearing recognized safety certifications like UL Type IC or ETL for commercial use.

Why Choose Beauty STC Lighting

Looking for high-quality 110V strip LED lights? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED lighting solutions. Our 110V LED strips are engineered for superior performance, durability, and energy efficiency, ideal for residential, commercial, and industrial applications. As a global supplier, we offer OEM and ODM services, competitive pricing, and reliable delivery.

To learn more or request a custom quote, contact our sales manager today at [email protected]. Let Beauty STC illuminate your next project with excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.